TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Cylinder Block (001-026)

Section 1 - Cylinder Block - Group 01

Page 1-67

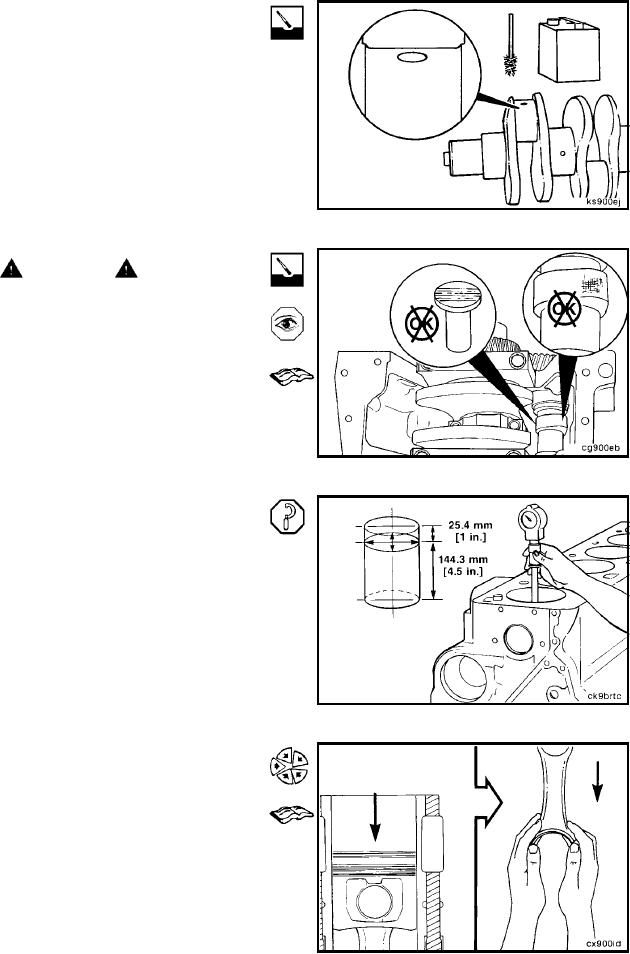

NOTE: Be sure to remove the covering from the piston

cooling nozzles.

Remove the protective tape and cloth, and clean the crank-

shaft journals.

WARNING

When using solvents, acids, or alkaline materials for

cleaning, follow the manufacturer's recommendations

for use. Wear goggles and protective clothing to avoid

personal injury.

Use a solvent and a brush to clean any residue that pos-

sibly has splashed on the camshaft.

Inspect the camshaft lobes and tappet faces for signs of

wear or damage. Refer to Procedure 001-008.

Inspect for Reuse (001-026-007)

Measure the cylinder bore diameter at 25.4 mm [1 in] and

170.7 mm [6.7 in] from the top of the cylinder block.

Bore I.D. Max - 102.116 mm [4.0203 in]

Bore out of round - 0.035 mm [0.0014 in]

Bore taper - 0.076 mm [0.003 in]

NOTE: Do not proceed with in-chassis overhaul if the cyl-

inder bores are worn beyond specifications.

Assemble (001-026-025)

Install the piston and connecting rod assemblies. Refer to

Procedure 001-054.

L-745