TM 5-2420-230-24-2

Piston and Connecting Rod Assembly (001-054)

B3.9 and B5.9 Series Engines

Page 1-102

Section 1 - Cylinder Block - Group 01

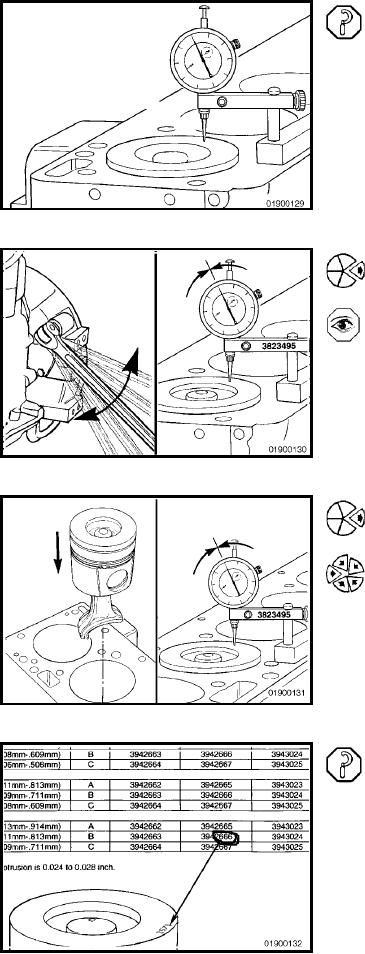

Move the dial indicator directly over the piston pin to elimi-

nate any side-to-side movement. Do not place the indicator

tip on the anodized area.

Rotate the crankshaft to top dead center (TDC). Rotate the

crankshaft clockwise and counterclockwise to find the

highest dial indicator reading.

Record the reading.

Remove the piston/connecting rod assembly from the No.

1 cylinder, and install the assembly into the No. 2 cylinder.

Repeat the procedure for every cylinder using the same

piston/connecting rod assembly.

The four digits on top of the piston are the last four digits

of the part number. Using the measured piston protrusion

and the grade of the piston that was measured, determine

the piston grade required to obtain protrusion of 0.610 to

0.711 mm [0.024 to 0.028 in].

L-780