TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Fuel Injection Pump, In-Line, Spill Port Timing (005-013)

Section 5 - Fuel System - Group 05

Page 5-35

Step: 2

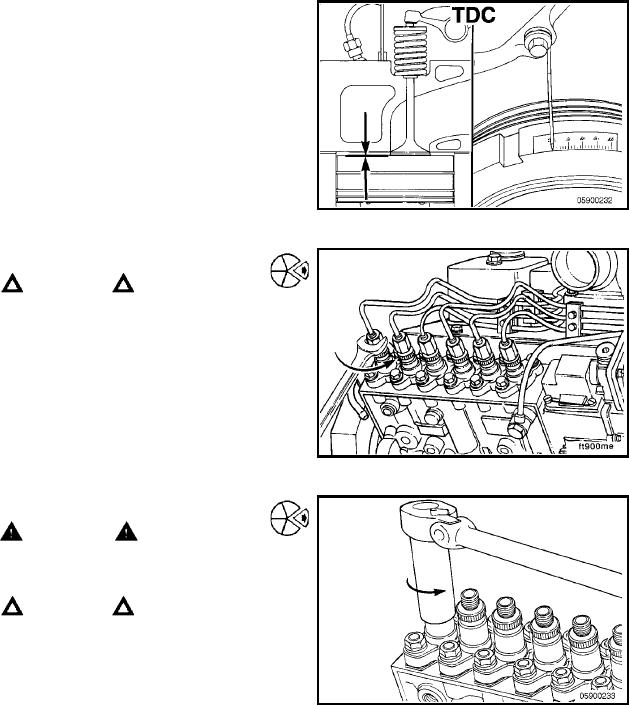

Locate top dead center (TDC) of the compression stroke on

cylinder No. 1. The following procedure uses the engine

timing pin, but other alternate methods, such as the dropped

valve method, can be used.

Step: 3

CAUTION

Do not bend the fuel lines. Bending the lines will cause

line or injector failure.

If the injection lines have not already been removed, re-

move the No. 1 injection line.

Step: 4

WARNING

Wear appropriate eye and face protection when using

compressed air. Flying debris and dirt can cause bodily

injury.

CAUTION

Do not loosen the two barrel flange nuts located below

the delivery valve holder. Loosening of these nuts will

void the fuel injection pump warranty.

NOTE: There is an external o-ring on the holder to help

prevent debris from getting into the pump; this can create

a slight resistance as the holder is loosened.

With the engine at TDC, loosen, but do not remove the front

(No. 1) delivery valve holder using the special socket pro-

vided in the timing kit. Use compressed air to remove any

paint chips from around the delivery valve holder. Remove

the special socket prior to removing the delivery valve

holder from the fuel injection pump.

L-895