TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Fuel Injection Pump, In-Line, Spill Port Timing (005-013)

Section 5 - Fuel System - Group 05

Page 5-37

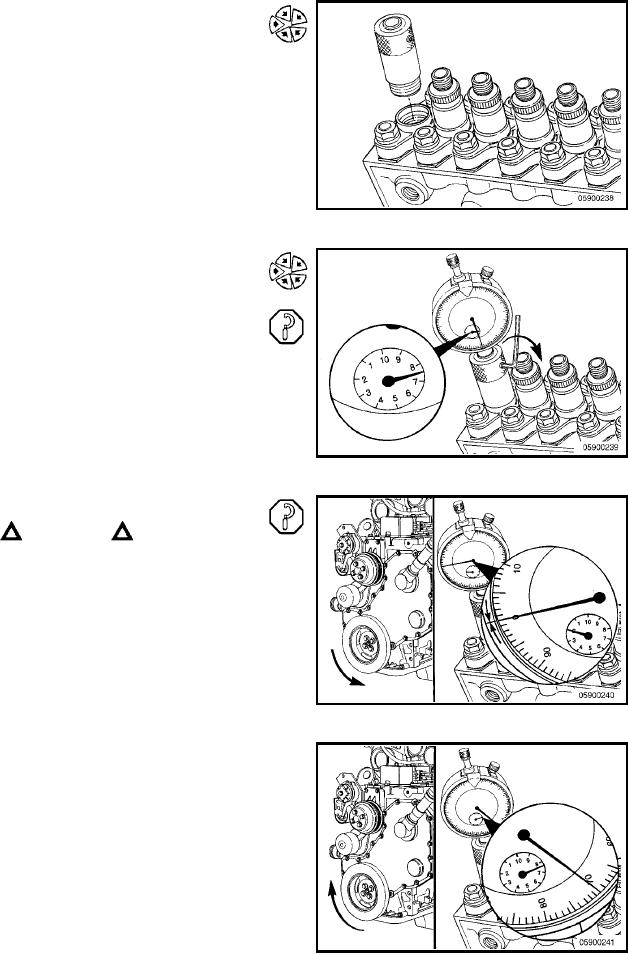

Step: 8

Install the dial indicator from the timing kit in place of the

No. 1 delivery valve holder and tighten finger-tight.

Step: 9

Loosen the set screw on the dial indicator adapter, and

install the dial indicator into the adapter. Position the dial

indicator to read between 7.0 and 9.0 mm, and lightly

tighten the set screw.

Overtightening the set screw will bind the dial indicator.

NOTE: The dial indicator is capable of measuring from 0 to

20.00 mm lift. The small inner dial is marked in increments

of 1.00 mm; the large outer dial is marked in increments of

0.01 mm. One revolution of the outer dial is equal to 1.00

mm. The inner dial only indicates 0 to 10.00 mm, but will

rotate twice as the indicator goes through the full range.

Step: 10

CAUTION

Be sure to disengage the timing pin before rotating the

crankshaft to avoid damage to the timing pin.

Use a barring tool to rotate the crankshaft in the direction

opposite normal direction of crankshaft rotation (counter-

clockwise from front of the engine) 1/4 turn or until the dial

indicator reading stops dropping. This is the inner base

circle of the fuel injection pump camshaft. Zero "0" the

indicator and note the reading on the small inner dial.

Step: 11

Rotate the crankshaft slowly to TDC in the direction of

normal crankshaft rotation (clockwise from front of the

engine).

The total lift must be within the specified lift for that CPL.

The attached table lists the lift setting in millimeters (mm)

that corresponds to the engine timing specification in

degrees.

L-897