TM 5-2420-230-24-2

Fuel Shutoff Valve (005-043)

B3.9 and B5.9 Series Engines

Page 5-72

Section 5 - Fuel System - Group 05

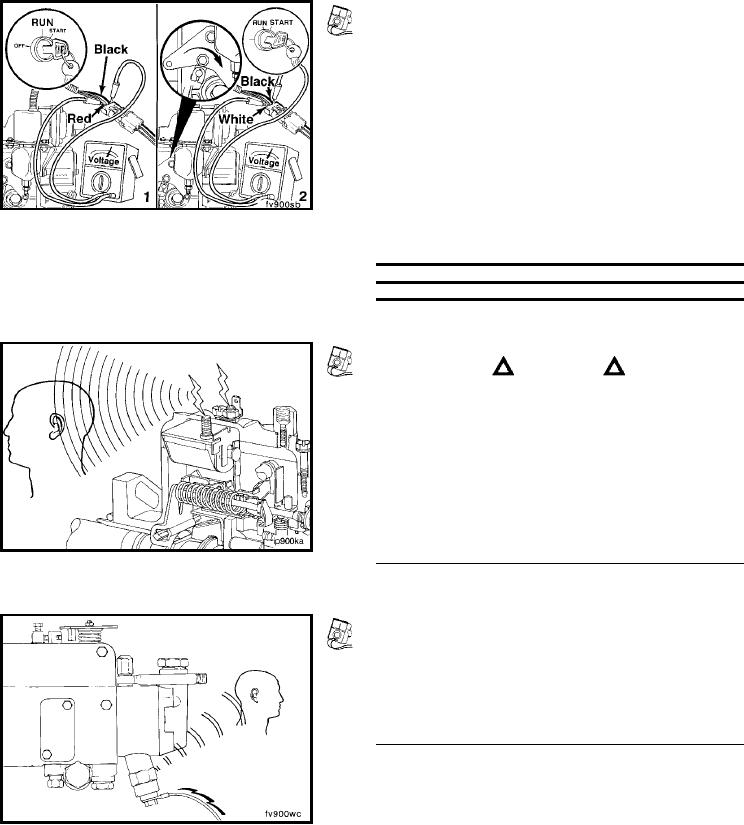

Voltage Check

To perform the solenoid voltage check, connect the wiring

harness, and apply voltage to the solenoid with the ignition

key as follows:

1. With the key in the RUN position, check the hold-in

voltage.

2. With the shutdown lever held in the shutdown position,

move the key to the START position, and check the

pull-in voltage.

Refer to the table for synchro start voltage specification

with solenoid at 20C [68F]. Voltage requirements will be

higher as engine temperature rises; therefore, these values

are only valid with the solenoid at normal ambient tem-

peratures.

Solenoid Voltage

Minimum Voltage

Pull-in

Hold-in

12

8.5

5.2

24

17.0

9.4

CAUTION

Do not check energize-to-run solenoid operation with

governor cover removed from the fuel injection pump.

Test the shutdown solenoid on the Stanadyne DB4 fuel

injection pump by applying an electrical current to the

terminals and listening for a ''click." If a solid ``click'' is

heard, the solenoid is operating freely.

Use the following values to check energize-to-run sole-

noids with an ohmmeter:

Stanadyne DB4 Solenoid

VDC

VDC to Energize (Minimum)

12

8.8

24

17.6

When the valve on the Lucas CAV DPA/DPS pump opens,

a ``click'' can be heard.

Use the following values to check the solenoid with an

CAV Solenoid Values

VDC

Resistance Ohms

VDC to Energize

(Minimum)

12

9 @ 22C [71.6F]

9

24

36 @ 22C [71.6F]

18

L-932