TM 5-2420-230-24-2

Lubricating Oil Pump (007-031)

B3.9 and B5.9 Series Engines

Page 7-26

Section 7 - Lubricating Oil System - Group 07

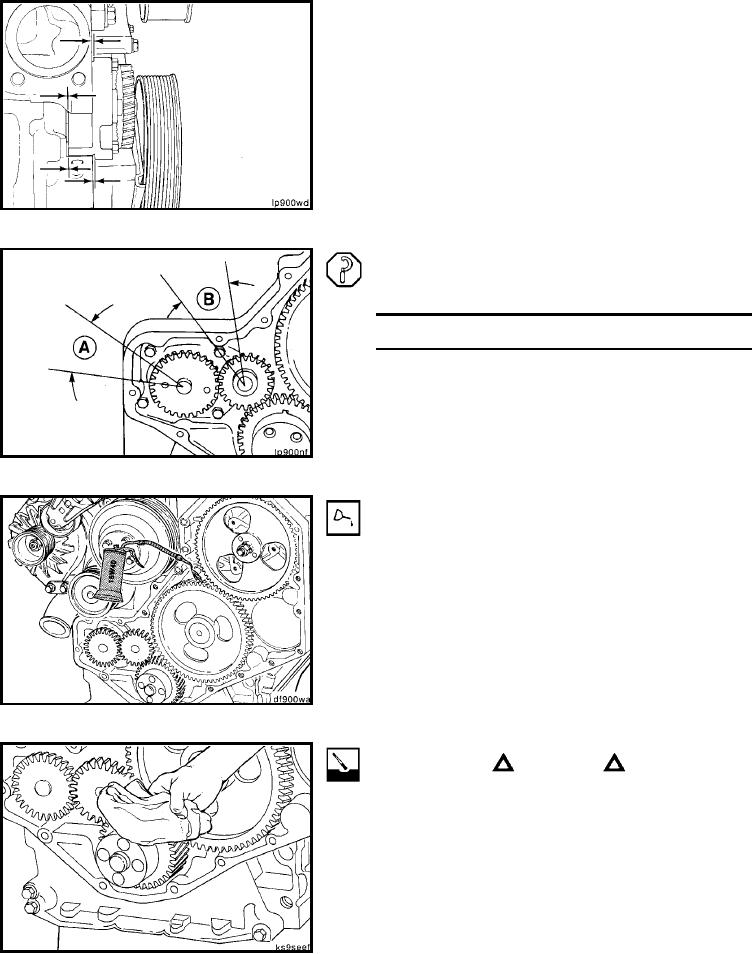

NOTE: The back plate on the pump seats against the

bottom of the bore in the cylinder block. When the lubri-

cating oil pump is correctly installed, the flange on the

lubricating oil pump will not touch the cylinder block.

NOTE: Be sure the gear backlash is correct if installing a

new lubricating oil pump.

Measure the gear backlash.

Backlash Limits

mm

in

A

0.076

MIN

0.003

0.330

MAX

0.013

B

0.076

MIN

0.003

0.330

MAX

0.013

NOTE: If the adjoining gear moves when you measure the

backlash, the reading will be incorrect.

Gear Cover - Installation

Lubricate the front gear train with clean lubricating engine

oil.

CAUTION

The seal lip and the sealing surface on the crankshaft

must be free from all oil residue to prevent seal leaks.

Thoroughly clean the front seal area of the crankshaft.

NOTE: Always replace the front seal when removing and

installing the gear cover.

L-1038