TM 5-2420-230-24-2

Lubricating Oil Contamination (007-044)

B3.9 and B5.9 Series Engines

Page 7-32

Section 7 - Lubricating Oil System - Group 07

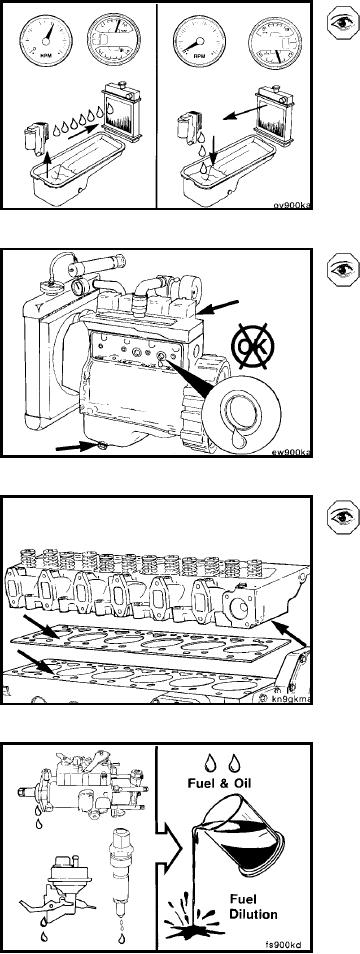

During operation, the lubricating oil pressure will be higher

than coolant pressure. A leak in the lubricating oil cooler

will show as lubricating oil in the coolant.

However, following an engine shutdown, the residual pres-

sure in the coolant system can cause coolant to seep

through the leak path into the lubricating oil.

To check for leaks, pressurize the cooling system to 140

kPa [20 psi]. With the system pressurized, remove the

following components, and inspect for leaks.

Valve covers (leaks indicate cracked head)

Lubricating oil drain plug (leaks indicate defective

lubricating oil cooler, head gasket, cracked head or

block)

Tappet cover (expansion plug leak).

Coolant in the lubricating oil can be caused by a damaged

cylinder head gasket or cracked cylinder head or block.

Remove the cylinder head and gasket, and inspect for

cracks or damage.

Fuel-Diluted Lubricating Oil

Fuel dilution is limited to five sources:

1. Injection pump shaft seal

2. Fuel leaking by the rings

3. Fuel transfer pump

4. A crack in the cylinder head from the fuel filter location

to the air intake

5. Injector leakage.

L-1044