TM 5-2420-230-24-2

Engine Testing (Chassis Dynamometer) (014-002)

B3.9 and B5.9 Series Engines

Page 14-6

Section 14 - Engine Testing - Group 14

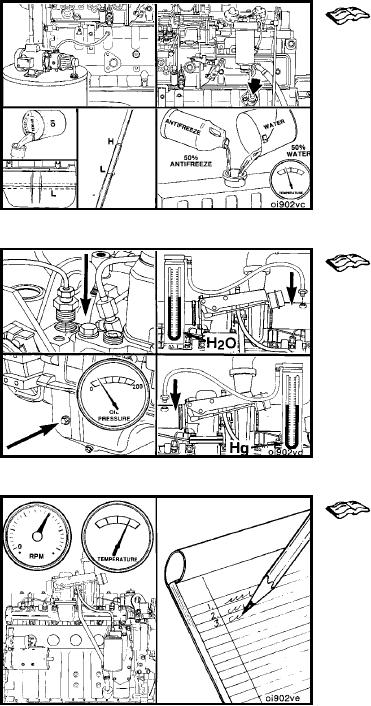

Test (014-002-012)

The following procedure assumes that the lubricating oil

and fuel systems were correctly primed, the dipstick cali-

brated, and the engine filled to the correct levels with lu-

bricating oil and coolant during installation of the engine

into the chassis. If these systems were not serviced during

installation of the engine, refer to Procedure 014-006 for

instructions on priming the lubricating oil and the fuel sys-

tem requirements, and calibrating the dipstick. Refer to the

Operation and Maintenance Manual, B Series, Bulletin No.

3810205, for instructions on filling the lubricating oil and

the cooling systems.

The number of instruments and gauges required to perform

a chassis dynamometer test will vary according to the type

and the capability of the test equipment used.

Refer to the service tools listed at the beginning of this

section.

To monitor an engine's performance correctly, record the

following parameters:

Exhaust back pressure

Lubricating oil pressure (vehicle instrument panel)

Coolant temperature (vehicle instrument panel)

Coolant pressure*

Intake manifold pressure*

Inlet air restriction*

Blowby*

Engine speed (rpm) (vehicle instrument panel)

Wheel horsepower (WHP) (dynamometer controls)

Fuel supply pressure.

*See the following for the Service Tools required and the

installation locations on the engine.

L-1304