TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Engine Testing (Chassis Dynamometer) (014-002)

Section 14 - Engine Testing - Group 14

Page 14-7

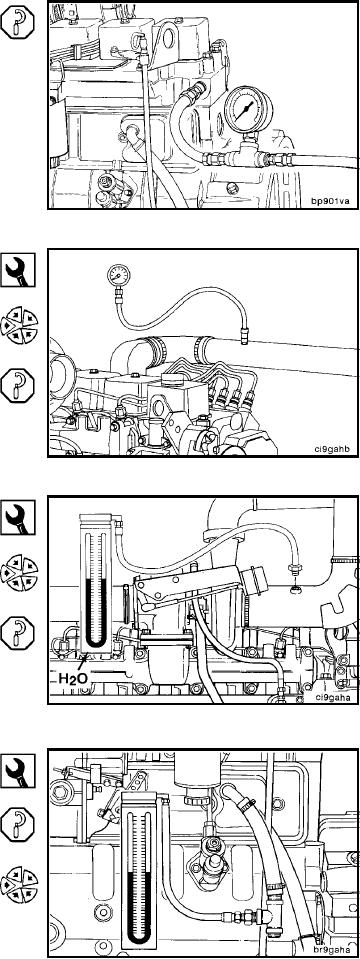

Measure the coolant pressure at a coolant tap on the ex-

haust side of the cylinder head.

Minimum Gauge Capacity:

415 kPa

[60 psi]

Pressure Gauge, Part No. ST-1273

Install a pressure gauge, Part No. ST-1273, in the location

shown.

Measure the intake manifold pressure (turbocharger boost).

Minimum Gauge Capacity:

1905 mm Hg

[75 in Hg]

Water Manometer, Part No. ST-1111-3

Vacuum Gauge, Part No. ST-434

Connect a water manometer, Part No. ST-1111-3, to the

turbocharger air inlet pipe to test air restriction.

NOTE: The manometer connection must be installed at a

90 degree angle to the airflow in a straight section of pipe,

one pipe diameter before the turbocharger, and be in be-

tween the turbocharger and the air filter.

NOTE: A vacuum gauge, Part No. ST-434, can be used in

place of the water manometer.

Minimum Gauge Capacity:

760 mm H2O

[30 in H2O]

Blowby Checking Tool, Part No. 3822476

Measure the blowby by installing blowby checking tool,

Part No. 3822476, in the crankcase breather vent. Connect

the blowby tool to a water manometer.

NOTE: Excessive blowby indicates a turbocharger mal-

function or an internal engine component malfunction, al-

lowing combustion gases to enter the crankcase.

Minimum Gauge Capacity:

1270 mm H2O

[50 in H2O]

L-1305