TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Engine Testing (Engine Dynamometer) (014-005)

Section 14 - Engine Testing - Group 14

Page 14-17

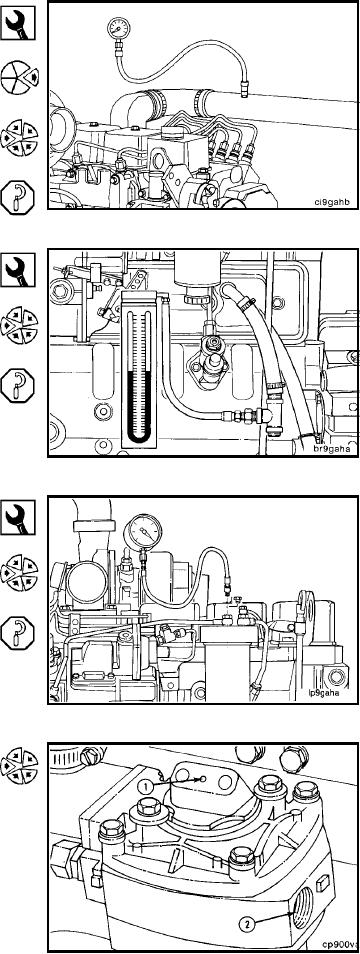

Pressure Gauge, Part No. ST-1273

To determine the amount of turbocharger boost, remove

the pipe plug in the air crossover tube.

Install the intake manifold pressure sensor or pressure

gauge, Part No. ST-1273.

Minimum Gauge Capacity:

1905 mm Hg

[75 in Hg]

Blowby Checking Tool, Part No. 3822476

Water Manometer, Part No. ST-1111-3

For accurate engine crankcase blowby measurement, in-

sert a blowby checking tool in the crankcase breather vent.

Connect a water manometer to the blowby tool. A pressure

gauge can be used in place of the manometer.

Minimum Gauge Capacity:

1270 mm H2O

[50 in H2O]

Vacuum Gauge, Part No. ST-434

To measure fuel filter restriction, connect vacuum gauge,

Part No. ST-434, to the injection pump inlet line.

Minimum Gauge Capacity:

760 mm Hg

[30 in Hg]

To be able to unload the compressor, connect a source of

compressed air to the unloader (1). This air line must

contain a valve between the source and the unloader.

NOTE: All air compressors manufactured by Cummins En-

gine Company, Inc. must be loaded during engine run-in.

All air compressors must be unloaded during the engine

performance check.

NOTE: The compressed air load in the accompanying il-

lustration must be attached to the air compressor outlet (2).

L-1315