TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Engine Run-in (Engine Dynamometer) (014-006)

Section 14 - Engine Testing - Group 14

Page 14-21

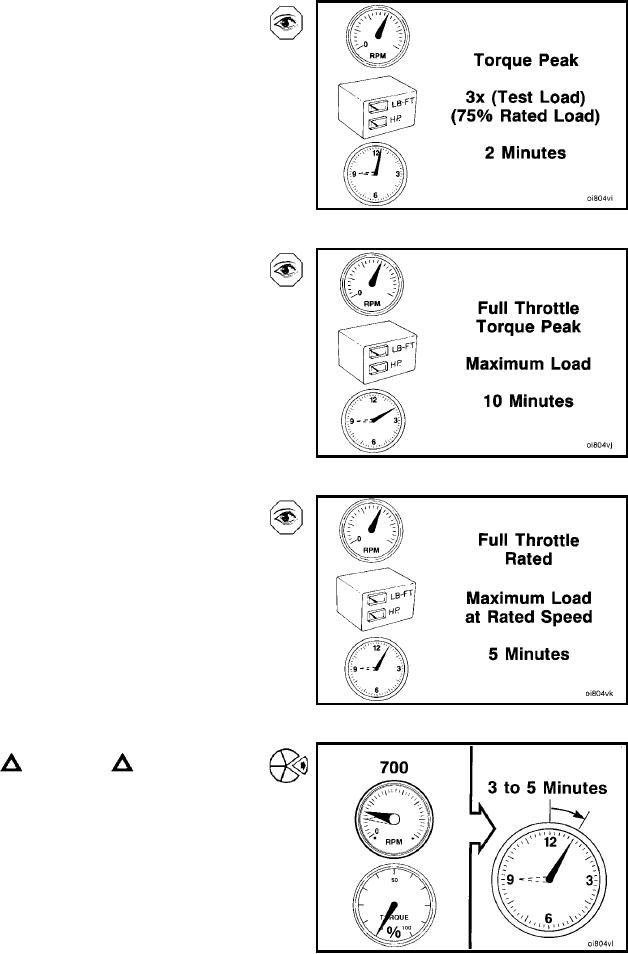

With the engine speed remaining at torque peak rpm, in-

crease the dynamometer load to 75 percent of torque peak

load. Operate the engine at this speed and load level for 2

minutes.

Check all gauges, and record the data.

NOTE: Do not proceed to the next step until blowby is

stable and within specification.

Move the throttle lever to its full capacity in the opened

position, and increase the dynamometer load until the en-

gine speed is at torque peak rpm. Operate the engine at

this speed and load level for 10 minutes, or until the blowby

becomes stable and within specification.

Check all gauges, and record the data.

Reduce the dynamometer load until the engine speed in-

creases to the engine's rated rpm.

Operate the engine at rated rpm for 5 minutes.

Check all gauges, and record the data.

CAUTION

Shutting off the engine immediately after operating at

full load will damage the turbocharger and internal com-

ponents. Always allow the engine to cool before shut-

ting it off.

Remove the dynamometer load completely, and operate

the engine at 700 rpm for 3 to 5 minutes. This period will

allow the turbocharger and other components to cool.

L-1319