TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Engine Run-in (Engine Dynamometer) (014-006)

Section 14 - Engine Testing - Group 14

Page 14-19

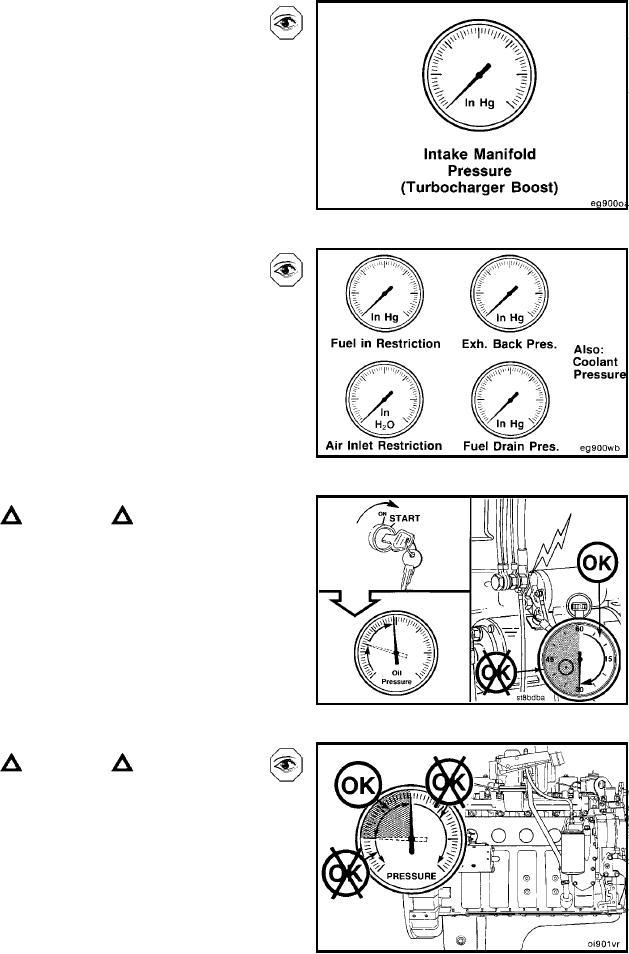

To evaluate the engine's performance correctly, this addi-

tional measurement must be observed during engine run-in

phases.

It is good practice to observe these measurements even if

engine performance meets specifications. If engine per-

formance does not meet specifications, these measure-

ments can indicate possible reasons for nonperformance.

CAUTION

Do not crank the engine for more than 30 seconds.

Excessive heat will damage the starting motor.

Crank the engine and observe the lubricating oil pressure

when the engine starts. If the engine fails to start within 30

seconds, allow the starting motor to cool for 2 minutes

before cranking the engine again.

CAUTION

If the lubricating oil pressure is not within specifica-

tions, shut off the engine immediately. Low lubricating

oil pressure will cause severe engine damage.

Engine lubricating oil pressure must be at least 69 kPa [10

psi] at 700 rpm.

Correct the problem if the lubricating oil pressure is not

within specifications.

L-1317