TM 5-2420-230-24-2

Engine Testing (In Chassis) (014-008)

B3.9 and B5.9 Series Engines

Page 14-24

Section 14 - Engine Testing - Group 14

NOTE: Low compression on a single cylinder can be caused

by an external leak or a leak to a coolant passage. A leak

to a coolant passage of this magnitude will also result in

coolant in the cylinder.

A compression leak to the coolant will normally be detected

by a loss of coolant as the coolant is blown from the cooling

system.

Service Tip: Remove the drive belt from the water pump.

Refer to Procedure 008-002 for removal and installation of

drive belt.

Run the engine for 1 to 2 minutes, and check for coolant

being blown from the radiator by compression gases.

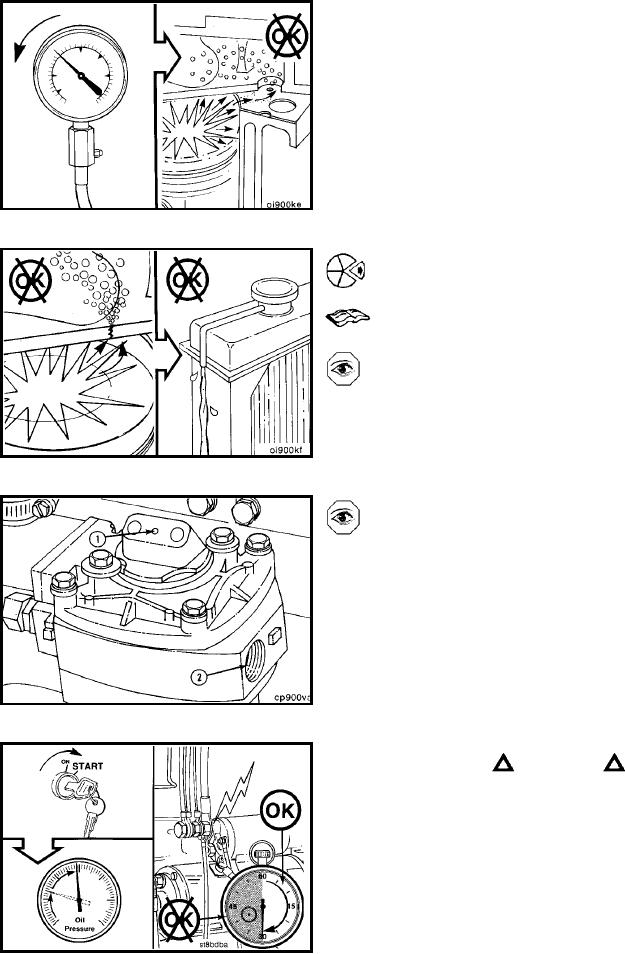

Test (014-008-012)

NOTE: The compressed air load in the accompanying il-

lustration must be attached to the air compressor outlet (2).

Make sure the air compressor will be unloaded during the

performance check.

Apply regulated air pressure of 655 kPa [95 psi] to the air

compressor unloader (1).

CAUTION

Do not crank the engine for more than 30 seconds.

Excessive heat will damage the starting motor.

Crank the engine and observe the oil pressure when the

engine starts. If the engine fails to start within 30 seconds,

allow the starting motor to cool for 2 minutes before crank-

ing the engine again.

L-1322