TM 5-2420-230-24-2

Engine Run-in (Engine Dynamometer) (014-006)

B3.9 and B5.9 Series Engines

Page 14-20

Section 14 - Engine Testing - Group 14

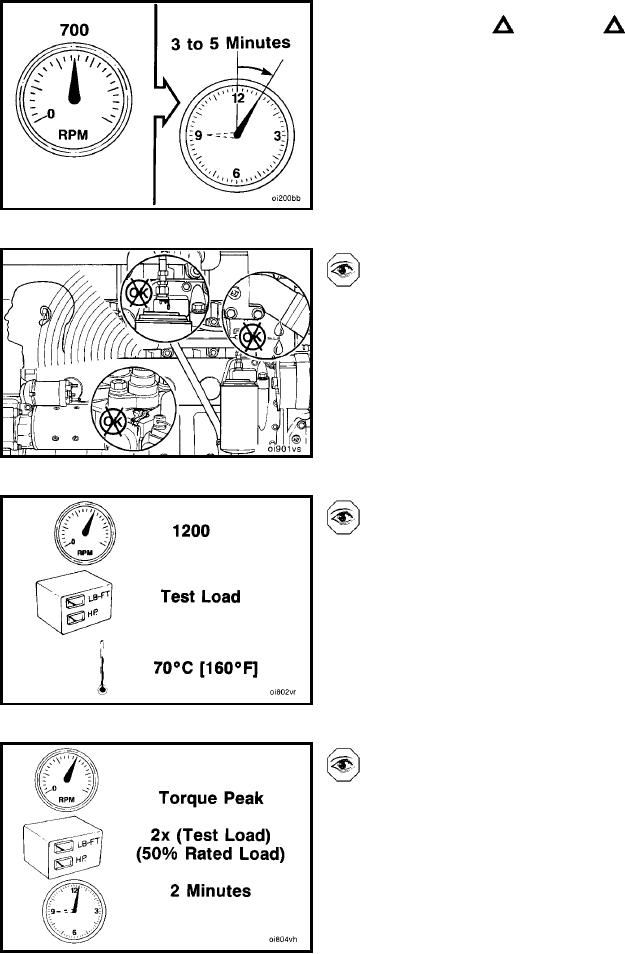

CAUTION

Do not operate the engine at idle speed longer than

specified during engine run-in. Excessive carbon de-

posits will form in cylinders, causing damage to the

engine.

Operate the engine at approximately 700 rpm for 3 to 5

minutes.

Listen for unusual noise; watch for coolant, fuel, and lu-

bricating oil leaks.

Check for correct engine operation.

NOTE: Repair all leaks or component problems before

continuing the engine run-in.

Move the throttle to obtain 1200-rpm engine speed, and set

the test load to 25 percent of the rated load.

Operate the engine at this speed and load level until the

coolant temperature is 70C [158F].

Check all gauges, and record the data.

NOTE: Do not proceed to the next step until a steady

blowby reading is obtained.

Open the throttle to the speed at which peak torque occurs,

and adjust the dynamometer load to 50 percent of torque

peak load. Operate the engine at this speed and load level

for 2 minutes.

Check all gauges, and record the data.

NOTE: Do not proceed to the next step until blowby is

stable and within specification.

L-1318