TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Engine Testing (In Chassis) (014-008)

Section 14 - Engine Testing - Group 14

Page 14-25

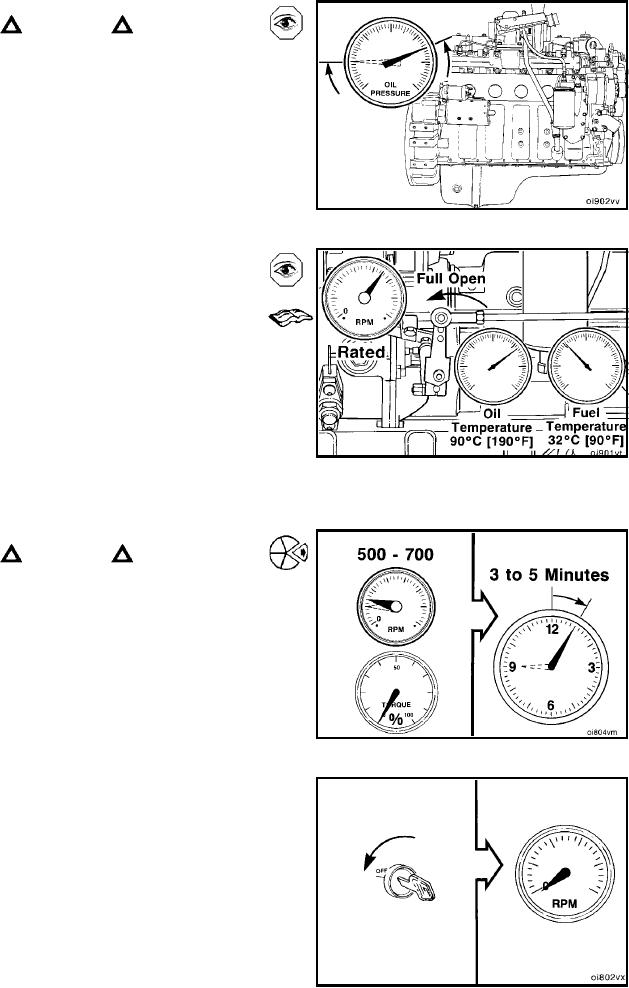

CAUTION

If the lubricating oil pressure is not within specifica-

tions, shut off the engine immediately. Low lubricating

oil pressure will cause engine damage. Correct the prob-

lem if lubricating oil pressure is not within specifica-

tions.

Engine lubricating oil pressure must be at least 69 kPa [10

psi] at approximately 700 rpm.

NOTE: The horsepower readings will not be accurate if the

lubricating oil temperature and fuel temperature are not

within specifications.

Make sure the engine is at operating temperature.

Move the throttle lever to the FULL-OPEN position. Adjust

the dynamometer load until the engine maintains the rated

rpm.

Allow the readings to stabilize. Read the horsepower.

Check all gauges, and record the readings.

Lubricating Oil Temperature

90 C

[194 F]

Fuel Temperature

32 C

[90 F]

CAUTION

Do not shut off the engine immediately after it has been

loaded. It must be allowed to cool sufficiently. Failure

to do so will result in engine damage.

NOTE: Idle periods longer than 5 minutes are to be avoided.

Remove the dynamometer load completely, and operate

the engine at idle speed for 3 to 5 minutes. This will allow

the turbocharger and other components to cool.

Shut off the engine after the cooldown period.

L-1323