TM 5-3805-280-10

Remote

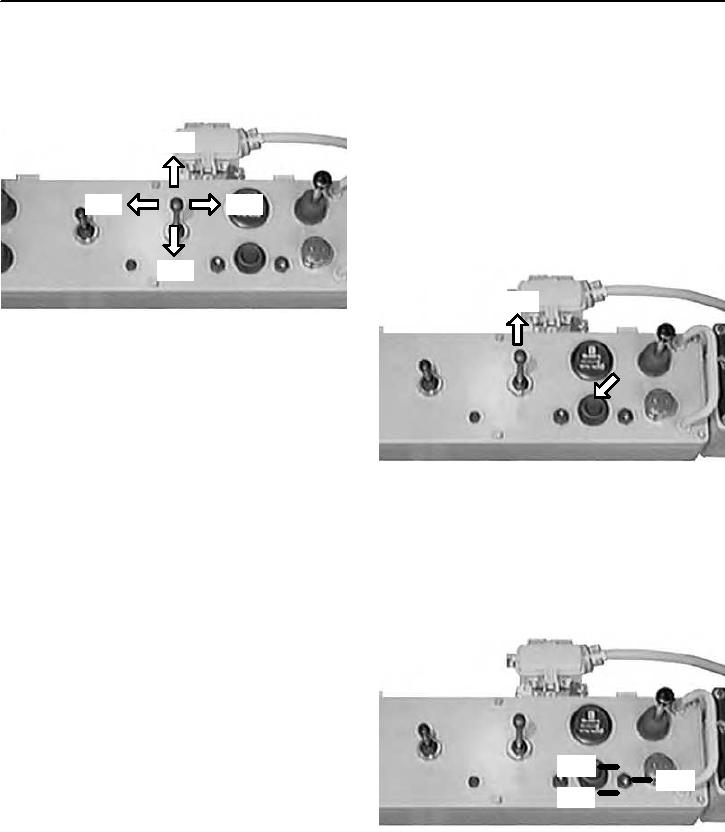

control operator's panel

Air flushing

Drifter control

Pull the lever to operate air flushing.

This is a fourway lever.

Dust hood control

C2

Pull the lever to slide the dust hood down.

Push the lever to slide the dust hood up.

C4

C3

Thread loosening button

C1

C2

C1 ) Pull the lever to operate normal rotation

only.

C2 ) Push the lever to operate reverse rotation

only.

Note : these two functions are never used for

thread coupling or uncoupling.

C3 ) Swing the lever in this direction to drill with

Depress this button to operate drifter percussion

automatic control.

only. By successive impulses to the drifter control in

C2 direction operate reverse rotation to break loose

This is the normal lever position when drilling.

the threaded joints.

The lever is locked in position.

HP / Dust collector switch

C4 ) Swing the lever in this position to drill on

manual.

This is a 3 positions switch.

In this specific position, the drilling automatics are

inoperative.

This lever position is exceptionally used to get full

reverse percussion (if the drifter is so equipped), or to

force the drilling when encountering faults by over

riding the antijamming.

J2

in such an occasion, rod jamming is risky.

J1

Carefully reduce the feed speed by switching the

J0

feed control in collaring position.

J0)

Down, HP flow is diverted to tank.

Drifter hourmeter

J1) Middle, HP pressure built up to allow move-

The drifter hourmeter indicates the total operating

ments or auxiliaries.

of the drifter.

J2)

Up, the dust collector is activated.

It should be used to determine service mainte-

nance.

Emergency stop button

Press the button to switch down the engine in case

Hydraulic centralizer control

of emergency only.

Pull the lever to open the centralizer.

The emergency stops selector must be placed

on CPA position (refer to safety).

Push the lever to close the centralizer.

7-44