TM 5-3805-280-10

Maintenance--Every 500 Hours

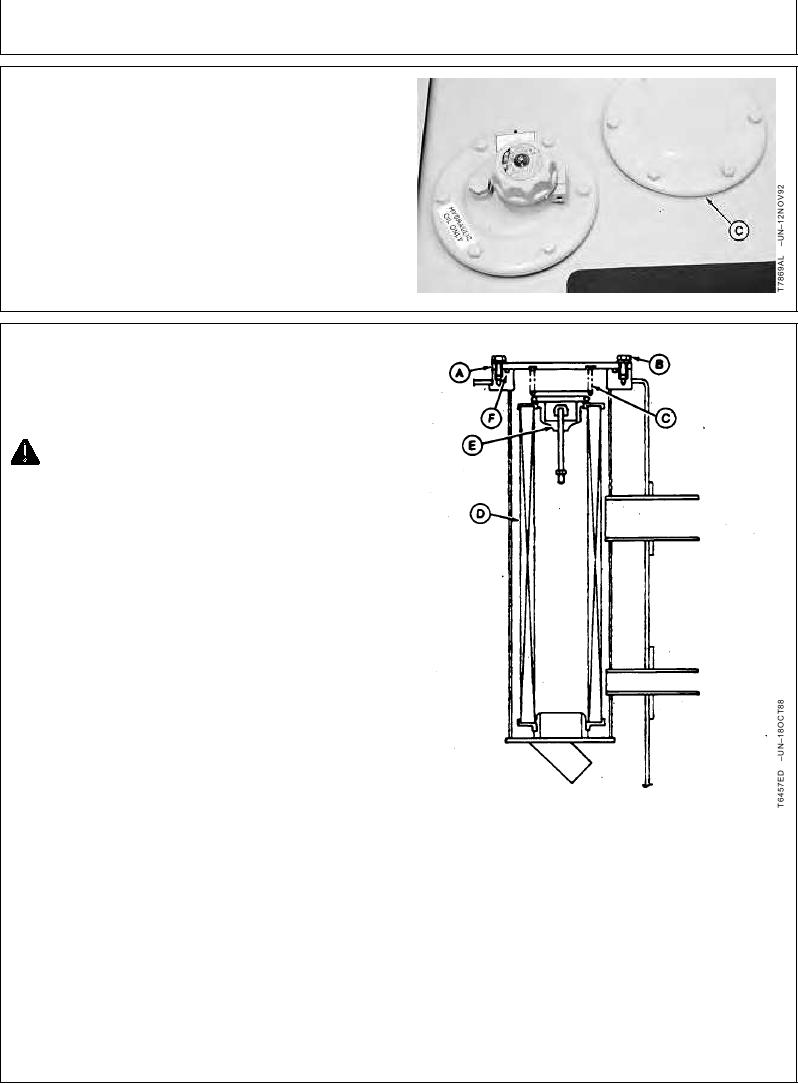

11. Hold down filter cover (C) against light spring load

when removing the last two cap screws.

TX,80,DH5100

1908JUL963/4

12. Remove spring (C), valve (E), and element (D).

13. Remove filter case and discard element and O-ring

(F).

CAUTION: Prevent possible injury from flying

chips if compressed air is more than 210 kPa

(2.1 bar) (30 psi). Reduce compressed air to

less than 210 kPa (2.1 bar) (30 psi) when using

for cleaning purposes. Clear area of bystanders,

guard against flying chips, and wear personal

protection equipment including eye protection.

NOTE: Remove element and inspect for metal particles

and debris in bottom of filter can. Excessive

amounts of brass and steel particles can indicate

a hydraulic pump, motor, or valve malfunction, or

a malfunction in process. A rubber type of

material can indicate cylinder packing problem.

14. Clean filter case with diesel fuel and dry with

compressed air.

15. Install filter case, valve (E), and spring (C) in

reservoir.

16. Install cover (A) and tighten cap screws (B).

A--Cover

B--Cap Screw

Cover Cap Screw--Specification

C--Spring

D--Element

Torque ............................................................................. 49 Nm (36 lb-ft)

E--Valve

F--O-Ring

17. Tighten vent plug.

TX,80,DH5100

1908JUL964/4

15-7