TM 5-3805-280-10

Drifter

maintenance

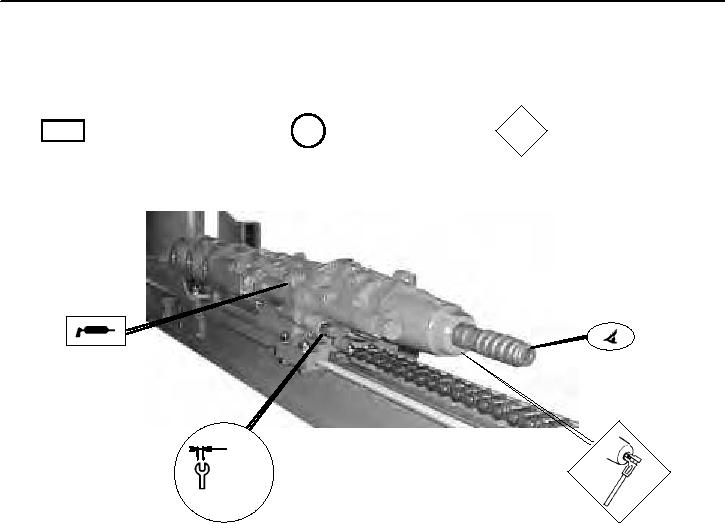

DRIFTER MAINTENANCE

. ea u / ( ( ( u 9aM 9

f

iM

e

, 8iMu

f

2 eeDM

f

med a

ec

N0 mm

1.28 in

6/ m 98

Daily

Every 1000 drilled meters

Dismount the shank adaptor to check the condi-

Lubricate the drifter front part (5 or 6 shots of a

tion of the splines.

hand grease pump).

Replace shank if damaged.

Check the wear of the flushing nozzle bronze bush

Weekly

(or front guide for drifter with reverse percussion).

Check tightening of drifter mounting bolts.

maximum wear = shank diameter+1 mm (.04 in).

Replace the complete flushing nozzle by a reno-

vated one if damaged (or replace the bronze bush for

drifter with reverse percussion).

19-12