TM 5-3805-280-10

Maintenance

intervals

DAILY

EVERY 50 HOURS

Wash the machine.

The CPA should be lowered in its rest position.

Check tightening of fixing cap bolts.

Attachment to carrier

Wipe all fittings before lubricating.

Check the CPA attachment to the carrier boom

Inspect all hoses. Replace if damaged.

end. Check all fixing pins are secured.

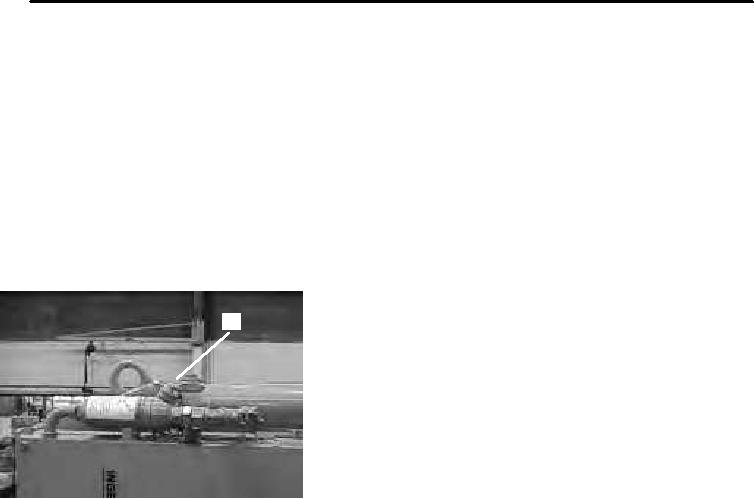

Pressurization air oiler

The oiler is located on the side of the CPA cradle,

close to the oscillation cylinder. Remove the oil fill

plug (Pos. 1) to add oil.

1

Drifter Front head lubrication

Wipe the fitting before lubrication.

Guide chains and ropes inspection

Examine the front chain in search of any

signs of wear or corrosion. replace if required.

Examine the whole length of the hose reel

rope. In particular, check the attachment points on the

tightener and the chain. The wire rope should not

show signs of abnormal wear (flats on the outside

strands, crushing, swelling or fraying).

In any case, replace the cable immediately if :

S there are at least 2 broken wires at an inter-

val of less than 36 mm (1.44 in) ( (6 times the nomi-

nal diameter of the cable)

S or, there are at least 4 broken wires at an in-

terval of less than 180 mm (7.2 in) (30 times the

nominal diameter of the cable)

S or, if the cable diameter is inferior to 5,4 mm

(.21 in) (nominal diameter of the cable less 10%).

Move the drifter at reduced speed until it reaches

its front end position.

Examine the chain reel in search of any

signs of wear or corrosion. Replace if required.

19-10