TM 5-3805-280-24-1

Sub-System Diagnostics

SPEED SENSE

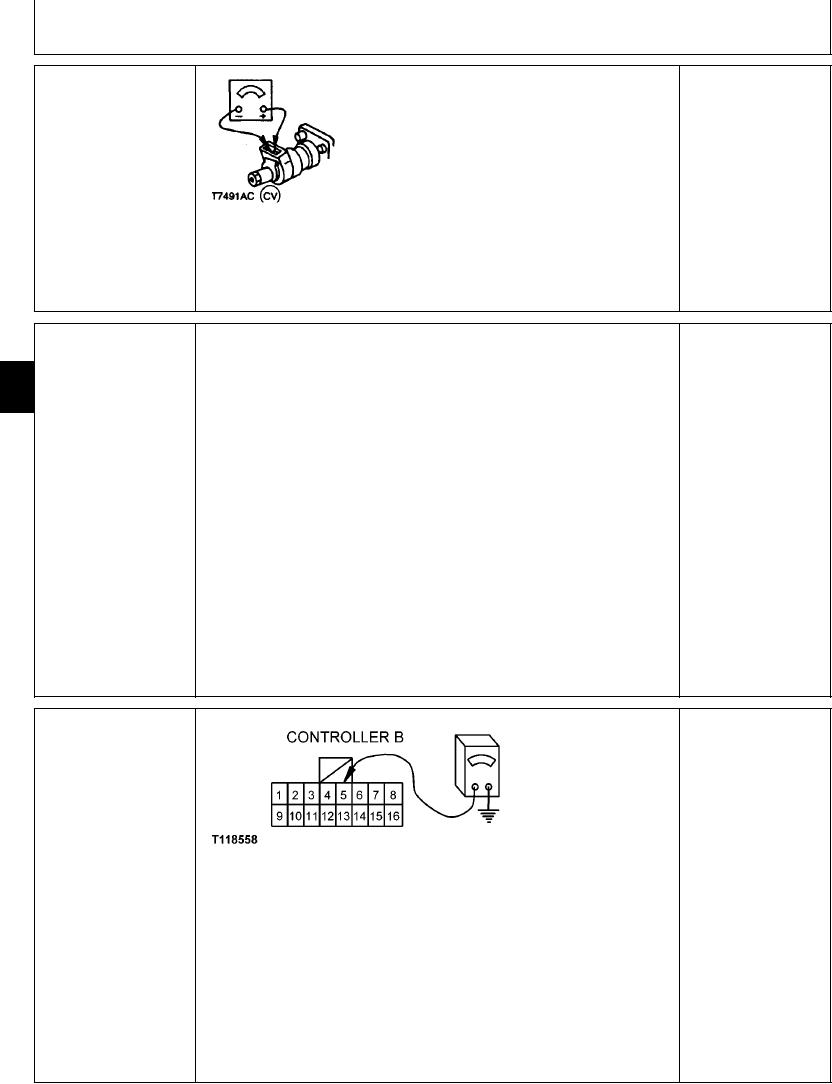

Turn key switch OFF.

YES: Solenoid is OK. Go

PROPORTIONAL

to next check.

SOLENOID (Y8) CHECK

Remove wire clip from bottom of solenoid harness

connector.

NO: Solenoid has failed.

Replace.

Disconnect harness from solenoid.

Connect ohmmeter to solenoid terminals.

T7491AC

UN08APR91

Does ohmmeter read approximately 24 ohms?

1/1

YES: Harness and engine

Turn key switch OFF.

SPEED SENSE

and pump controller are

PROPORTIONAL

9015

OK.

SOLENOID (Y8)

Install proportional solenoid test harness JT07352 in series with wiring harness and

15

HARNESS CHECK

sense solenoid.

94

NO: Harness or engine

and pump controller has

Connect voltmeter to test harness jacks.

failed. Repair or replace.

Start engine, set auto idle mode to OFF, and set engine idle to medium speed so that

voltmeter reads approximately 5.5 volts (RPM dial set at first bar after mid range).

Bottom arm in to load engine.

Does voltmeter read approximately 7 volts with arm bottomed in?

1/1

LEARNING SWITCH

YES: Switch and harness

(S16) CHECK

are OK.

NO: Switch or harness

has failed. Check and

repair or replace.

T118558 1921NOV98

Turn key switch OFF.

Disconnect 16-pin connector B from engine and pump controller.

Turn switch to ON.

Measure continuity from pins 5 of connector B to ground.

Is continuity measured?

1/1

4-159