TM 5-3805-280-24-1

Tests

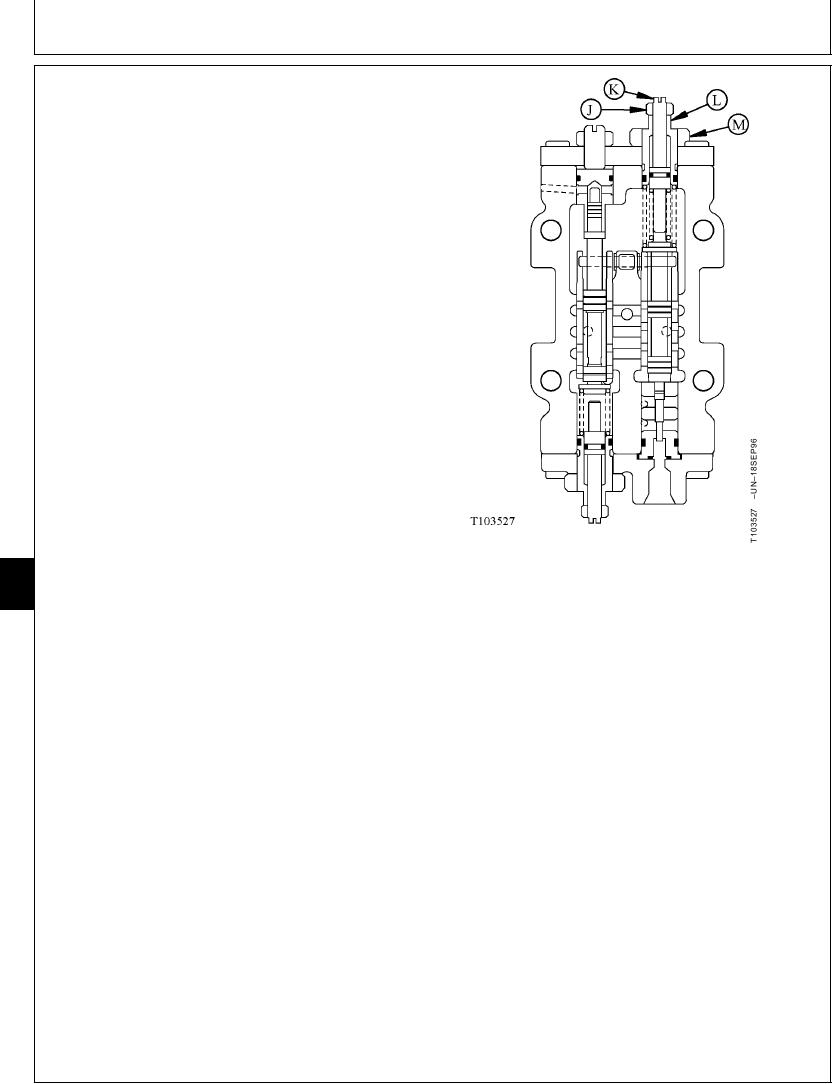

NOTE: Initial procedure is to adjust the load adjusting

cartridges (L) to match the two pumps before

making the final adjustment to get the combined

pump engine pulldown at medium pressure.

Hydraulic pressure increases as the load adjusting

cartridges are turned in because the pump flow is

increasing.

h. Turn the load adjusting cartridge (L) on front pump

regulator in until engine speed just starts to

decrease. Then, slowly turn the load adjusting

cartridge out and in to verify the exact point where

engine speed starts to decrease (0--10 rpm).

i. Turn the load adjusting cartridge (L) on rear pump

regulator in until engine speed just starts to

decrease. Then, slowly turn the load adjusting

cartridge out and in to verify the exact point where

engine speed starts to decrease (0--10 rpm).

j. Release both propel functions.

NOTE: To avoid heating the oil excessively, only operate

the propel functions over relief to check the

pulldown after each adjustment of cartridge.

9025

J--13 mm Nut

k. Turn both load adjusting cartridges (L) in equal

25

K--Load Adjusting Screw

amounts. Start with 1/4 turn.

110

L--Load Adjusting Cartridge

M--30 mm Nut

l. Actuate and hold both propel functions over relief to

check that engine pulldown speed is 2070--2080

rpm. Record the rpm reading. Release propel

functions.

Load Adjusting Cartridge (Outer Spring)--Combined Pump

Engine Pulldown--Specification

Speed ...................................................... 2070--2080 rpm at 17 235 kPa

(172 bar) (2500 psi)

with tracks stalled

m. Hold the cartridge and tighten large nut on both

regulators.

Continued on next page

TX,9025,GG2661 1906MAY978/14

6-241