TM 5-3805-280-24-1

Adjustment of drilling automatisms

ADJUSTMENT OF DRILLING AUTOMATISMS

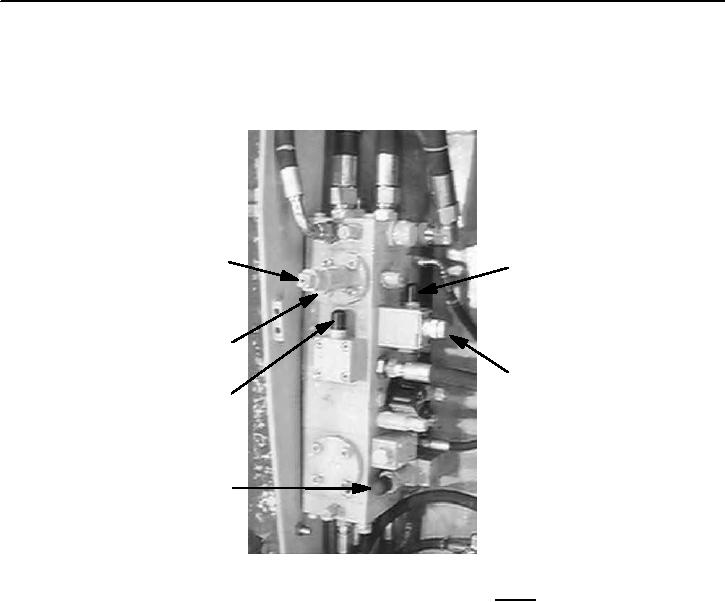

LOCATION OF ADJUSTING SCREWS

3

2

4

5

1

6

1)

V1 Feed pressure

4)

V3 Drifter power regulation

V3 measures actual feed force by sensing both

This valve setting is made while setting up the

forward and return feed pressures.

machine on site, to suit bit type and diameter.

The V3 adjustment sets the feed pressure limit

Presetting can be made in a static mode prior to

below which the drifter power will be reduced.

drilling by feeding the bit against some resistance.

This control will continue to reduce the drifter

Final setting is made at full percussion power

power level to a 60 bar (870 psi) preset minimum as

while drilling in the hardest, most homogeneous

rock resistance decreases.

competent rock encountered.

5)

Feed flow regulator

2)

MP Maximum percussion pressure

This flow regulator adjusts the feed maximum

flow to slightly above the drill rate in the hardest rock

It sets the drifter maximum percussion pressure

encountered.

when drilling with cold oil while starting up.

t If the feed flow while drilling in softer rock condi

ions reaches the preset maximum, the resulting

This factory setting must not be altered.

back pressure makes the feed force to decrease and

act on V3.

3)

V2 Operating percussion pressure

This acts as both an Anti-Void and Collaring

Control.

It sets the drifter percussion power to a suitable

level for bit size and rock hardness. The setting

6) V4 Progressive feed control and

should be approximately :

antijam

- 120 - 130 bar (1715- 1850 psi) for Hc 80

- 130 - 140 bar (1850 - 2000 psi) for Hc 120

V4 is an adjustable regulator which senses the

- 140 - 160 bar (2000 - 2285 psi) for Hc 150

pressure differential across the rotation motor and

depending upon the appropriate drifter power level.

acts directly upon feed flows.

10-10