TM 5-3805-280-24-1

Hydraulic System

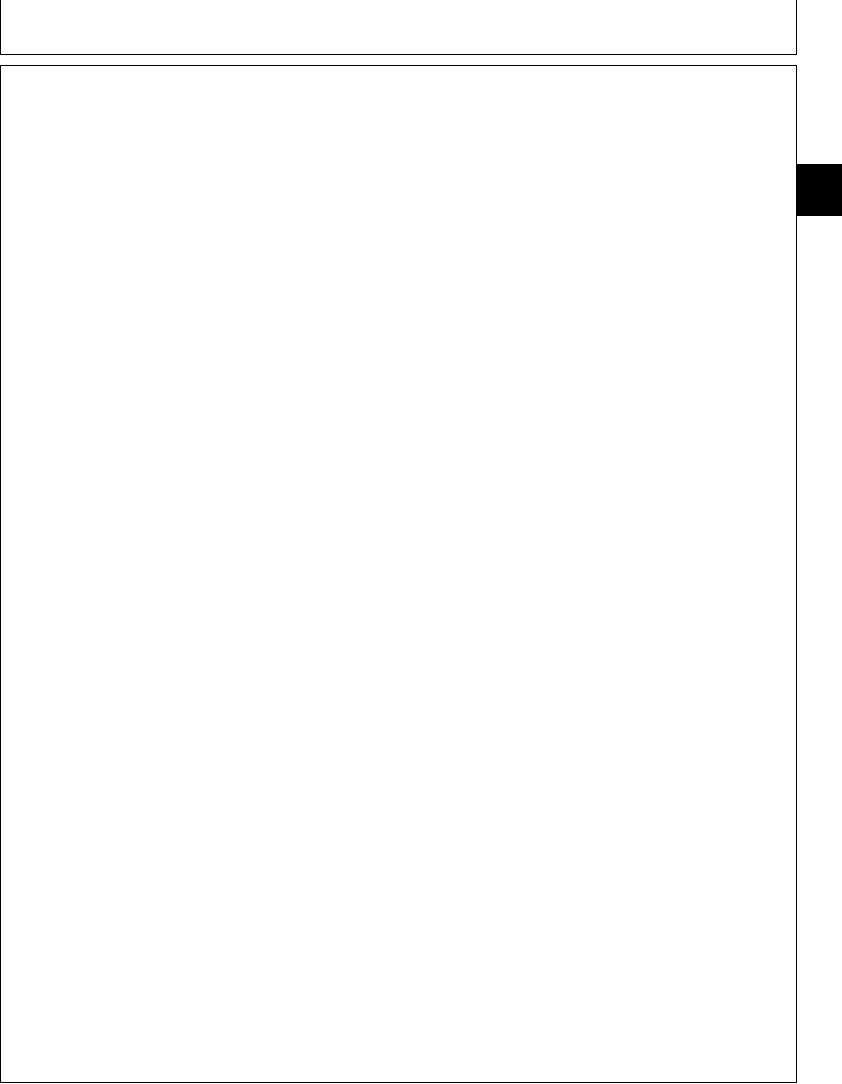

1A--Brake Valve Housing

15--Spring (2 used)

25--Plug

31--Plug

1B--Check Valve Poppet

17--Plug (2 used)

25A--O-Ring

32--O-Ring

1C--Counterbalance Valve

17A--O-Ring (2 used)

29--Servo Piston Shuttle

33--Plug (2 used)

07--Spring (2 used)

21--Crossover Relief Valve

and Brake Release

33A--O-Ring (2 used)

08--Spring (2 used)

(2 used)

Shuttle Ball (2 used)

35--Plug (5 used)

09--Stop (2 used)

23--Pressure Reducing

30--Servo Piston Shuttle

35A--O-Ring (5 used)

02

11--Plug (2 used)

Valve Spool

and Brake Release

0260

12--O-Ring (2 used)

24--Spring

Shuttle Seat (2 used)

27

Check Valve Plug--Specification

NOTE: Valves can be removed with propel motor on

the machine.

Torque................................................................... 235 Nm (173 lb-ft)

Apply a film of clean hydraulic oil to parts before

BRAKE PRESSURE REDUCING VALVE

assembly.

1. Remove brake pressure reducing valves (23--25).

CROSSOVER RELIEF VALVE

2. Tighten plug (25).

1. Remove crossover relief valves (21).

Brake Pressure Reducing Valve Plug--Specification

2. Check and adjust pressure setting. (See Propel

Motor Crossover Relief Valve Test and Adjustment

Torque....................................................................... 69 Nm (51 lb-ft)

in Group 9025-25.)

BRAKE RELEASE SHUTTLE VALVE

3. Tighten crossover relief valve plug.

1. Remove brake release shuttle valves (29--32).

Crossover Relief Valve Plug--Specification

2. Remove seat (30) using a 5 mm hex key wrench.

Torque................................................................... 540 Nm (400 lb-ft)

3. Seat may need to be heated to break down thread

COUNTERBALANCE VALVE

lock and sealer. This can be done by inserting a

steel rod into the hole and heating the rod to

1. Remove counterbalance valves (1C, 7--9, 11, and

transfer the heat to the seat.

12).

IMPORTANT: Oil will leak past ball if it is not

2. Tighten plug (11).

seated properly.

Counterbalance Valve Plug--Specification

4. Install ball (29).

Torque................................................................... 215 Nm (160 lb-ft)

5. Place ball on seat and tap ball with a hammer to

obtain a tight fit between ball and seat. After

CHECK VALVES

installing ball insert a metal bar into the plug hole

so it rests on the ball. Tap other end of bar with a

1. Remove check valves (1B, 15, and 17).

hammer to obtain a tight fit between ball and

housing.

2. Tighten plug (1B).

Continued on next page

TX,02,UU3724

1918SEP982/3

12-50