TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

REMOVE PISTONS AND CONNECTING RODS

10

13

If engine is to be removed from the machine, see your

machine technical manual.

CAUTION: Do not drain engine coolant until it

cools below operating temperature. Then slowly

loosen block drain valve to relieve any

pressure.

1. Drain coolant and engine oil.

NOTE: If engine is to be completely disassembled, see

ENGINE DISASSEMBLY SEQUENCE in Group

04.

2. Remove cylinder head. (See REMOVE CYLINDER

HEAD in Group 05.)

3. Remove camshaft followers and keep in order for

reassembly in same position.

4. Clean all foreign material from cylinder block top deck.

RG,10,DT7421 1912NOV971/5

IMPORTANT: Cap screws and washers must be

tightened to the correct specification to

achieve an accurate reading when

checking liner standout (height above

block), as detailed later in this group.

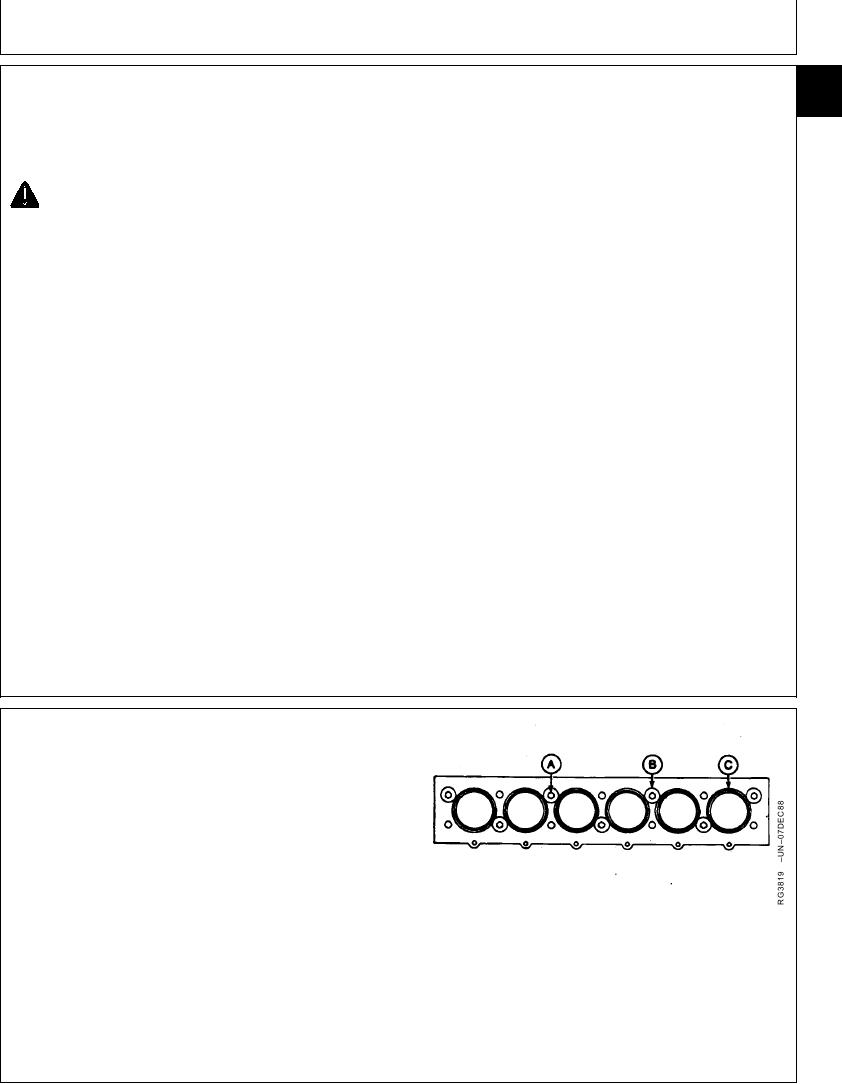

5. Use short cap screws (A) and 3 mm (1/8 in.) thick

washers (B) to bolt down cylinder liners (C). Fasten

each liner in two locations. Tighten cap screws to 68

Nm (50 lb-ft).

NOTE: Do not rotate crankshaft with cylinder head

A--Cap Screws

removed unless liners are fastened down.

B--Washers

C--Liners

Continued on next page

RG,10,DT7421 1912NOV972/5

13-126