TM 5-3805-280-24-2

Camshaft, Balancer Shafts and Timing Gear Train

REMOVE AND INSTALL CAMSHAFT

16

19

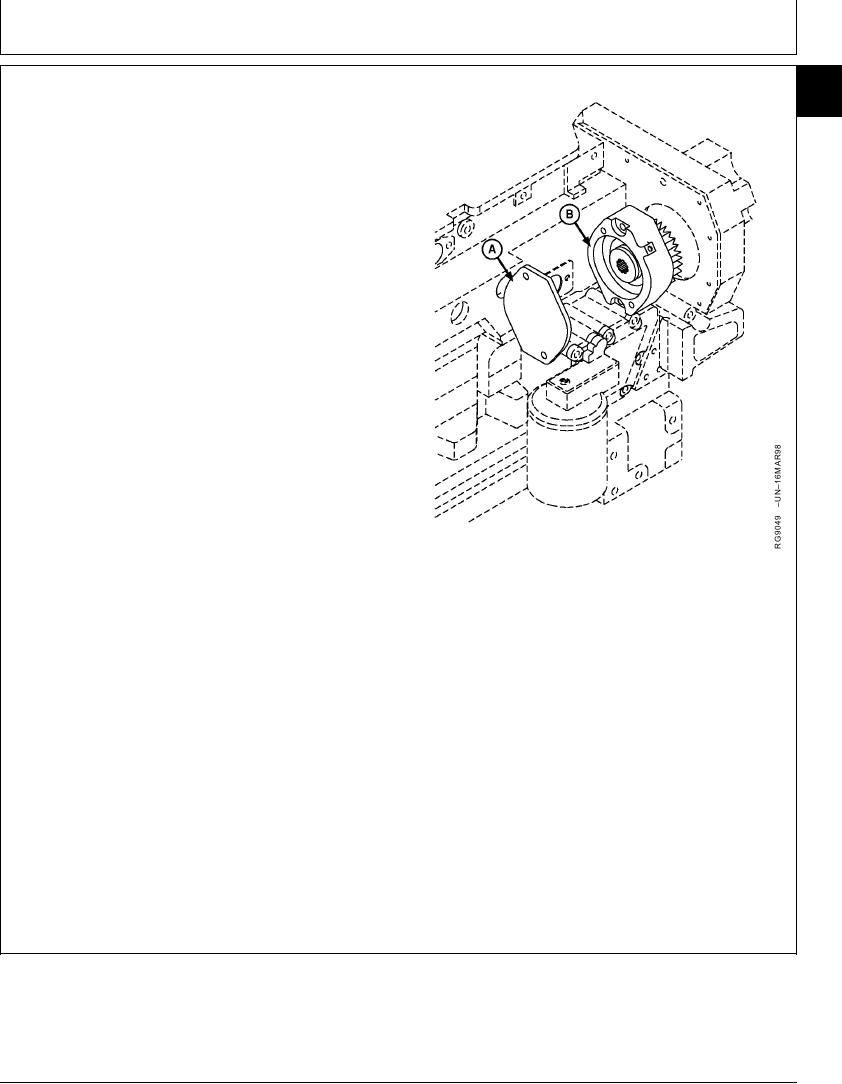

GEAR-DRIVEN AUXILIARY DRIVE

NOTE: Various auxiliary drive options are available;

removal and installation of all options are similar.

The auxiliary drive is integrated into the engine

front timing gear cover.

1. Remove lube line.

2. Remove auxiliary drive gear cover (A).

3. Clean and inspect cover for cracks or damage.

4. Remove auxiliary drive assembly (B).

NOTE: Auxiliary drive assembly is repairable. Refer to

CTM67 - OEM Accessories for additional service

information.

5. Inspect for cracked housing, worn or damaged

bearings, damaged gear or spline.

6. Repair or replace auxiliary drive assembly as needed.

7. Install gasket on auxiliary drive assembly and position

in the cylinder block plate. Install cap screws and

tighten to specifications.

A--Gear Cover

B--Auxiliary Drive Assembly

Auxiliary Drive-to-Cylinder Block Plate--Specification

Torque ............................................................................. 95 Nm (70 lb-ft)

8. Install cover and tighten cap screws or nuts to

specifications.

Auxiliary Drive Cover Plate--Specification

Torque ............................................................................. 55 Nm (41 lb-ft)

9. Install lube line.

RG,16,DT7504 1914NOV971/1

13-251