TM 5-3805-280-24-2

Lubrication System

20

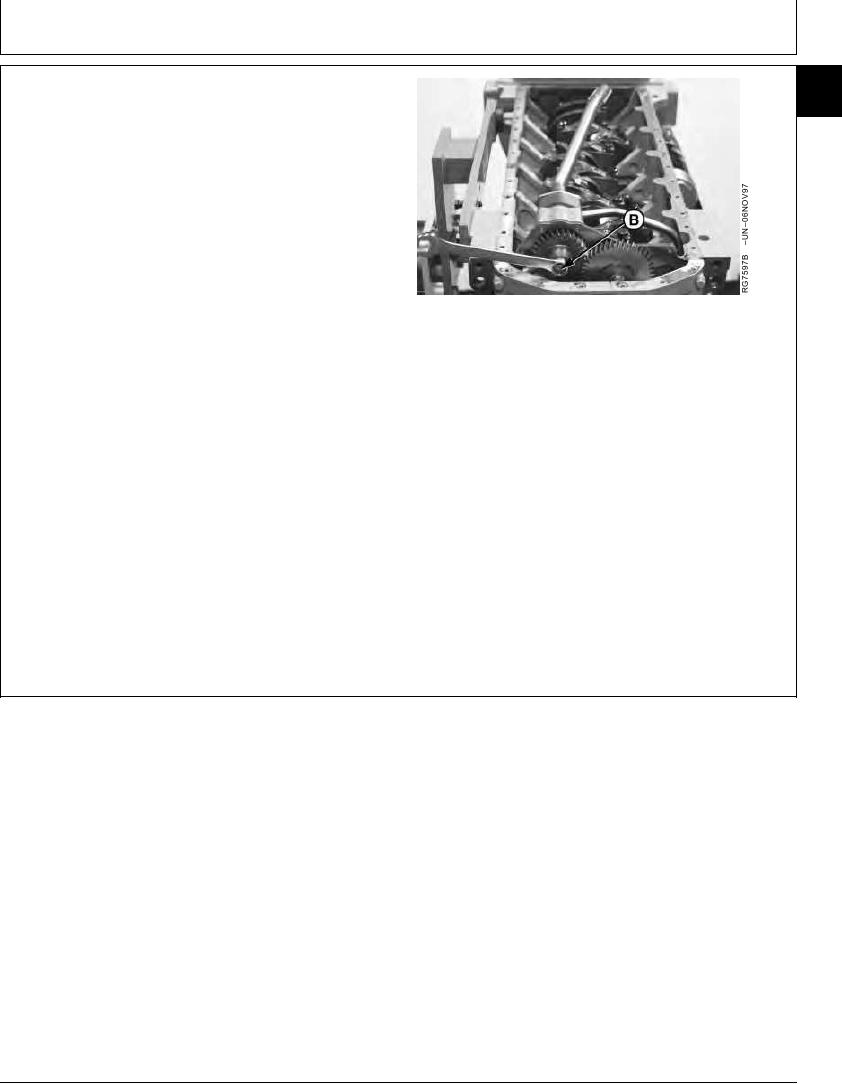

4. On 4-cylinder engines with balancer shafts, lock

21

crankshaft at TDC using JDG820 or JDE83 Flywheel

Turning Tool and JDE81-4 Timing Pin, then lock the

balancer shaft (inj. pump side) using a lock-grip plier

so that balancer shaft cannot turn while oil pump gear

is being removed.

IMPORTANT: When removing nut and gear from

tapered oil pump drive shaft, take care

not to damage fine threads on end of

shaft.

5. Remove nut (B) and pull gear from tapered oil pump

B--Gear Retaining Nut

drive shaft.

To remove oil pump gear, loosen nut several turns and

apply force between the front plate and gear on two

sides of gear with pry bars.

If above method does not work, loosen oil pump

housing cap screws and strike the nut on end of shaft

with a small lead hammer while applying force to gear

until gear is free of tapered shaft.

6. Remove oil pump pick-up tube, as described earlier in

this group.

Continued on next page

RG,20,DT7524 1917NOV972/3

13-314