TM 5-3805-280-24-2

Fuel System

35

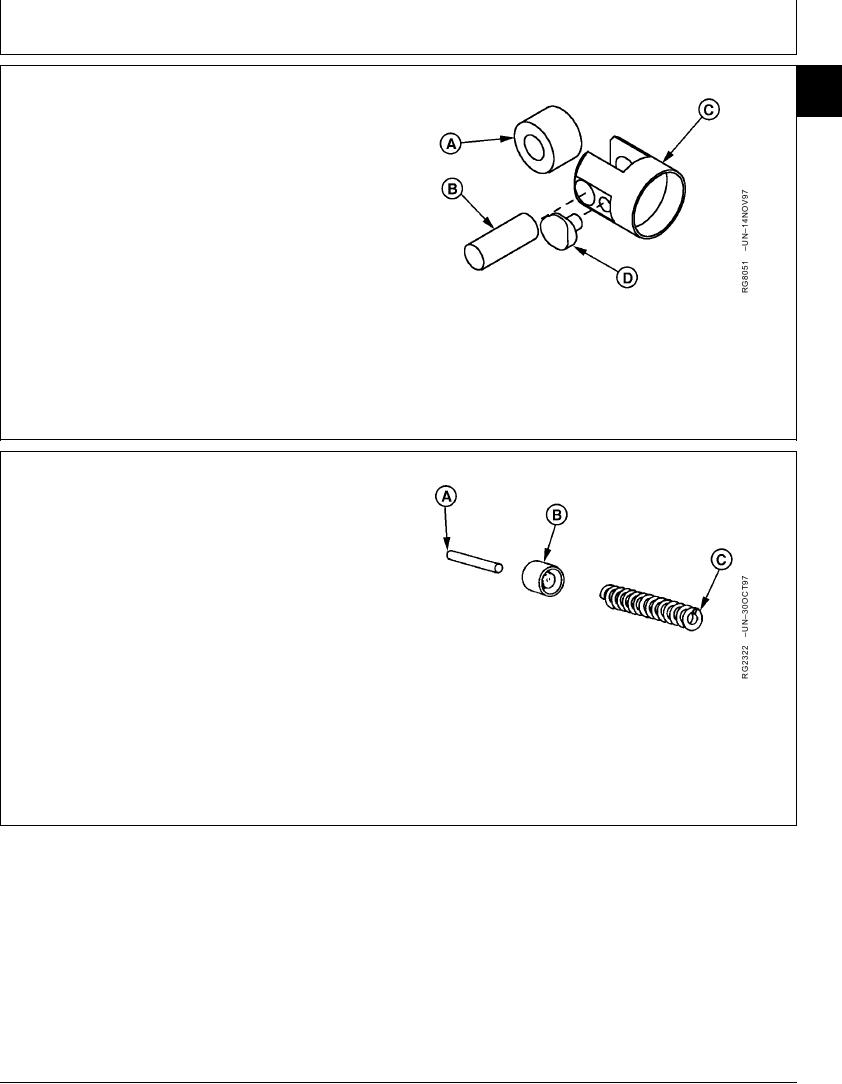

4. Inspect roller (A) OD for excessive wear. Be sure roller

27

turns freely on pin (B) and in tappet (C).

5. Inspect sliding blocks (D). Edges should be square and

unpitted. Blocks should slide in and out of tappet

easily.

6. Inspect tappet for wear and scoring. Remove any

deposits with a suitable solvent.

Be sure land on tappet that contacts pressure spindle

is flat and undamaged.

A--Roller

B--Pin

C--Tappet

D--Sliding Block (2 used)

RG,35,JW7615

1920NOV972/4

7. Inspect pressure spindle (A) and plunger (B) for pits

and burrs. Replace parts as necessary.

8. Inspect spring (C) for cracks and distortion. Replace

parts as necessary.

A--Spindle

B--Plunger

C--Spring

Continued on next page

RG,35,JW7615

1920NOV973/4

13-406