TM 5-3805-280-24-2

Fuel System

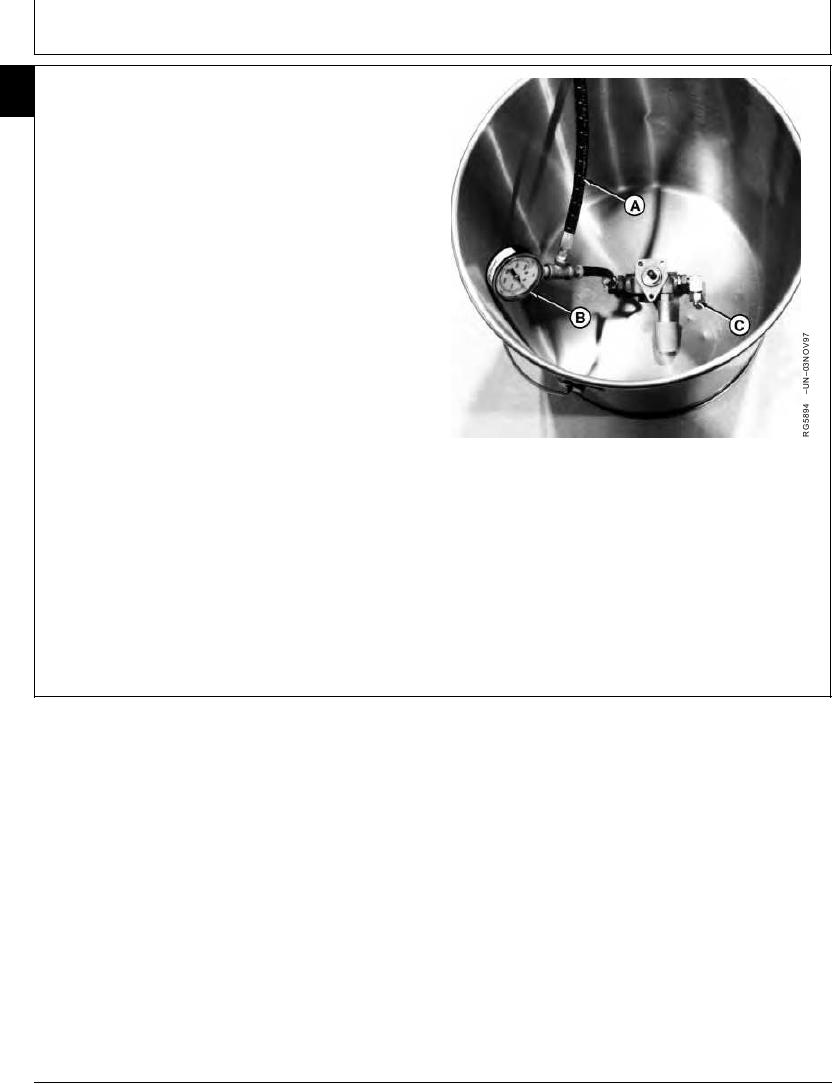

TEST IN-LINE FUEL SUPPLY PUMP FOR

35

22

LEAKS

Fuel delivery pressure should be checked before

removing supply pump from injection pump. (See CHECK

FUEL SUPPLY PUMP OPERATION, in Group 115.)

1. Connect compressed air line (A) to a pressure gauge

(B) and to supply pump inlet fitting. Air line should

have a regulating valve to control pressure.

2. Cap or plug supply pump outlet fitting (C).

3. Submerge supply pump in a container of clean diesel

fuel. Regulate air pressure to 200 kPa (2.0 bar) (29

psi).

4. Move roller tappet in and out by hand. No air bubbles

should appear around roller tappet.

NOTE: If bubbles appear, it is an indication that either the

A--Air Line

O-ring seal is defective or spindle or tappet is

B--Pressure Gauge

worn (or possibly both).

C--Outlet Fitting

IMPORTANT: Serious injection pump or engine

damage could occur, if enough diesel

fuel leaks past spindle and seal. Fuel

leakage past spindle dilutes engine oil.

RG,35,JW7617

1920NOV971/1

13-401