TM 5-3805-280-24-2

Fuel System

BENCH TEST FUEL SUPPLY PUMP

35

18

The following bench tests can be performed on a supply

pump installed on the engine when the pump is suspected

to be defective. (See MEASURE FUEL SUPPLY PUMP

PRESSURE in Group 115.)

Perform the Vacuum/Pressure Test and Leakage Test,

listed below. Replace the supply pump if either test shows

the pump to be defective, there is no repair procedure.

VACUUM/PRESSURE TEST:

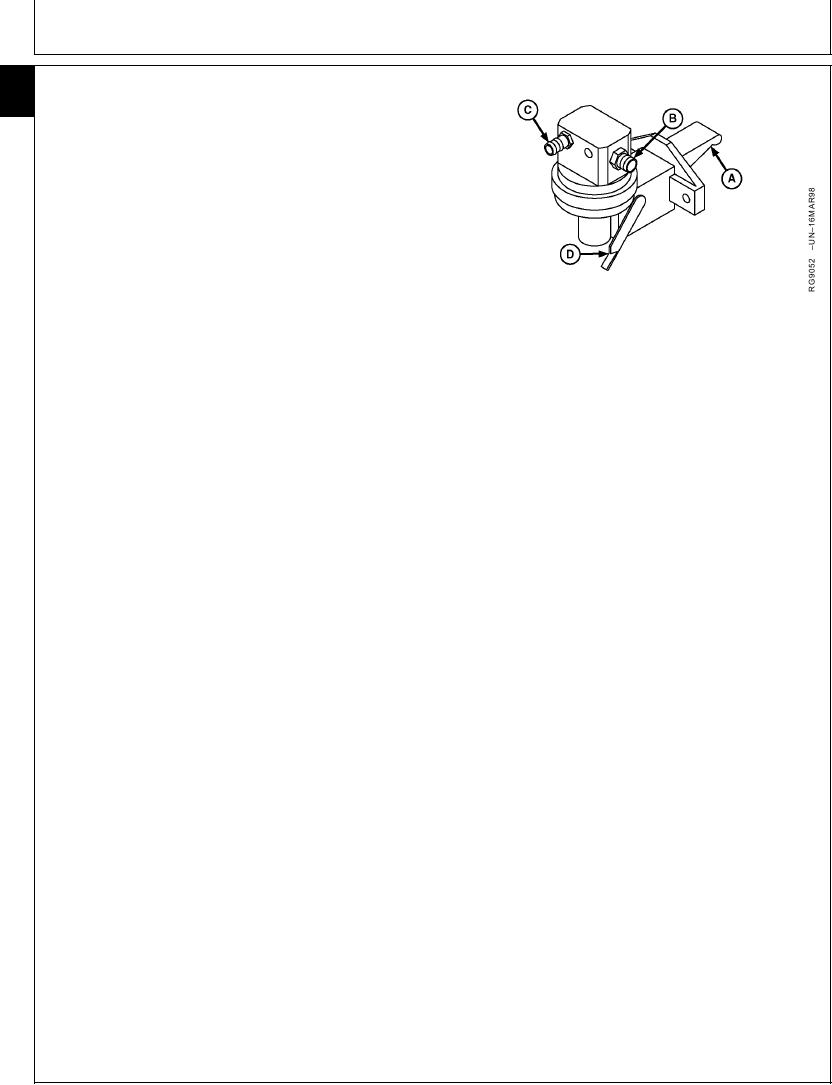

A--Lever

NOTE: This test will give a good indication of condition of

B--Outlet Side of Pump

both the inlet and outlet valves, as well as the

C--Inlet Side of Pump

diaphragm. The numerical values obtained on

D--Primer Lever

both the vacuum and pressure sides are not

important; rather it is the needle movement that is

important (very slow for a good pump; very fast or

not at all for a defective pump).

1. Remove inlet and outlet fittings.

2. Install vacuum/pressure gauge to inlet side of pump

(C).

3. Move primer lever (D) all the way downward. Release

lever and at the same time observe gauge:

The gauge needle should read the same value each

time, and then very slowly return to "0". This

indicates that the inlet valve and diaphragm are in

good condition. Proceed to next step.

If the gauge needle does not move at all, or the

needle rapidly returns to "0", the pump is defective

and must be replaced.

4. Remove vacuum/pressure gauge and install onto outlet

side of pump (B).

5. Move priming lever all the way to upward position.

Release lever and at same time observe gauge

reading:

Continued on next page

RG,35,JW7620

1920NOV971/3

13-397