TM 5-3805-280-24-2

Fuel System

The gauge needle should initially read 28--41 kPa

35

19

(0.28--0.41 bar) (4--6 psi), then return to "0" very

slowly. This indicates that the outlet valve and

diaphragm are in good condition. Supply pump is

operating properly and should be reinstalled on

engine.

Fuel Supply Pump--Specification

Pressure ....................................................... 28--41 kPa (0.28--0.41 bar)

(4--6 psi)

If the gauge needle initially reads same value as

above and then returns immediately back to "0", the

pump is defective and must be replaced.

RG,35,JW7620

1920NOV972/3

LEAKAGE TEST:

The leakage test should be performed if a supply pump

suspected of leaking fuel externally, or internally into the

engine crankcase.

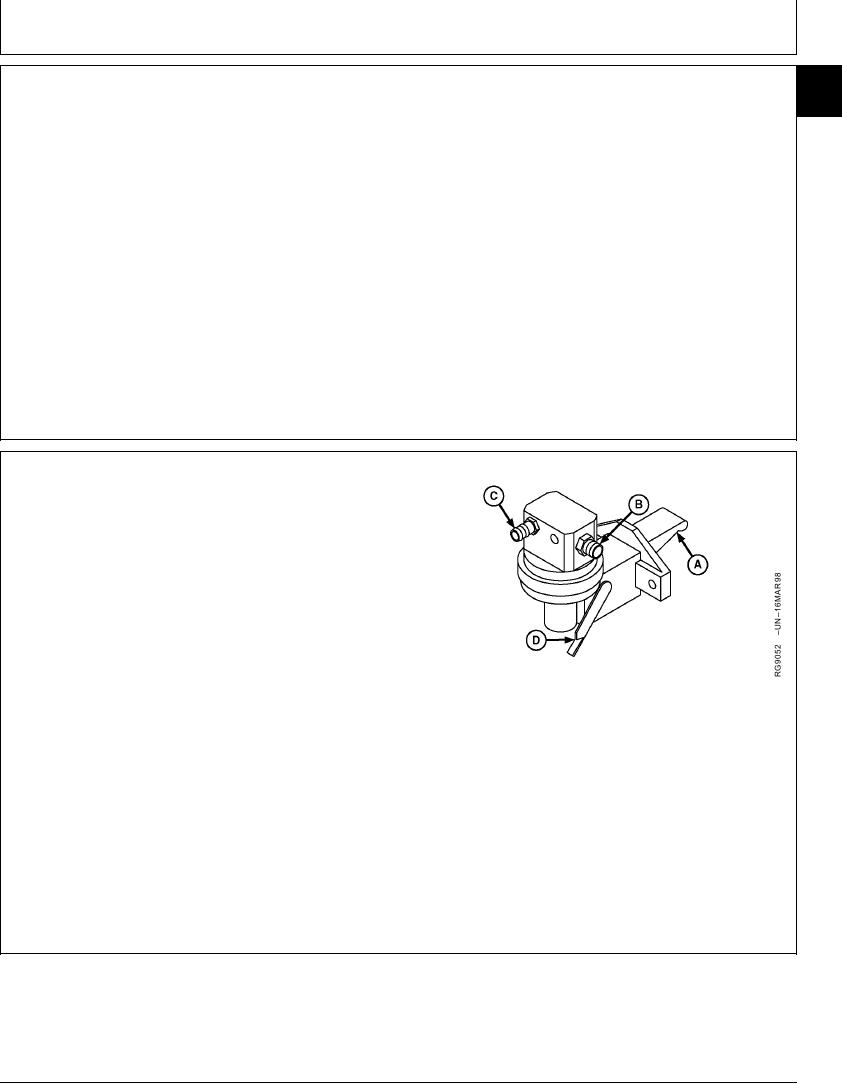

1. Install an air line on inlet side of pump (C) and apply

140 kPa (1.4 bar) (20 psi) pressure.

2. Hold finger over outlet side of pump (B) or install a

plug. Submerge pump into a container of clean diesel

fuel.

If air bubbles occur around banded connection

A--Lever

B--Outlet Side of Pump

holding the two halves of pump together (indicating

C--Inlet Side of Pump

leakage), replace pump.

D--Primer Lever

If the diaphragm is bad, there will be leakage

through vent holes (if equipped) and around the

rocker arm. Replace pump as necessary.

RG,35,JW7620

1920NOV973/3

13-398