TM 5-3805-280-24-2

Fuel System

35

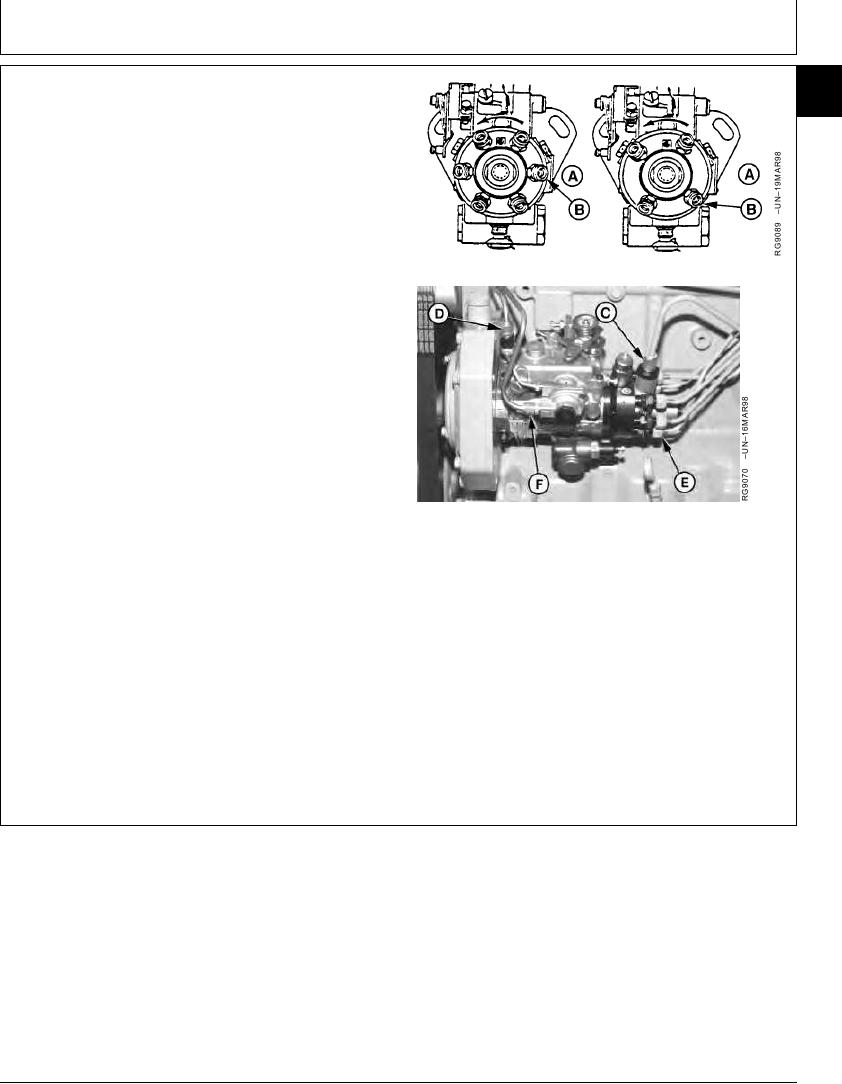

11. Connect injection pump pressure lines (E). Beginning

47

with outlet (B) and continue around the pump head in

counterclockwise direction, attaching lines in same

order as engine firing (1-5-3-6-2-4 on 6-cylinder

engines and 1-3-4-2 on 4-cylinder engines).

12. Tighten fuel delivery (pressure) lines at pump to

specifications, using a suitable 17 mm deep-well

socket.

6-Cyl Engine (Left) 4-Cyl Engine (Right)

Fuel Injection Pump Delivery Lines--Specification

Torque ............................................................................. 27 Nm (20 lb-ft)

IMPORTANT: ALWAYS use a backup wrench when

loosening or tightening fuel delivery

lines at fuel injection pump, so that the

pump discharge fittings are not altered.

This prevents possible internal pump

damage.

13. Connect fuel supply line (C), fuel return line (D) and

aneroid line (F).

14. Connect fuel shut-off cable and speed control linkage,

if equipped. Install and securely tighten electrical

A--Engine Block Side

B--Outlet Connection to No. 1 Cylinder

connections to shut-off solenoid and throttle

C--Fuel Supply Line

positioning solenoid, if equipped. Connect cold start

D--Fuel Return Line

switch, if equipped.

E--Fuel Delivery (Pressure) Lines

F--Aneroid Line

15. Bleed air from fuel system as outlined in Group 115.

Start engine, run for several minutes and check entire

fuel system for leaks.

RG,35,JW7603

1920NOV975/5

13-426