TM 5-3805-280-24-2

Fuel System

35

NOTE: Leakage rate based on use of No. 2 diesel fuel or

67

an equivalent viscosity of test oil at 18--24C

(65--75F) ambient temperature.

3. Look for leakage from the return end of nozzle. After

one drop, leakage should be within specifications.

Fuel Injection Nozzle Return Leakage at Pressure Test of 10300 kPa

(103 bar) (1500 psi)--Specification

Leakage .............................................................. 3--10 Drops/30 Seconds

If nozzle leakage is not within specified range, nozzle

must be reconditioned as outlined later in this group.

RG,35,JW7592

1920NOV976/6

DISASSEMBLE FUEL INJECTION NOZZLES

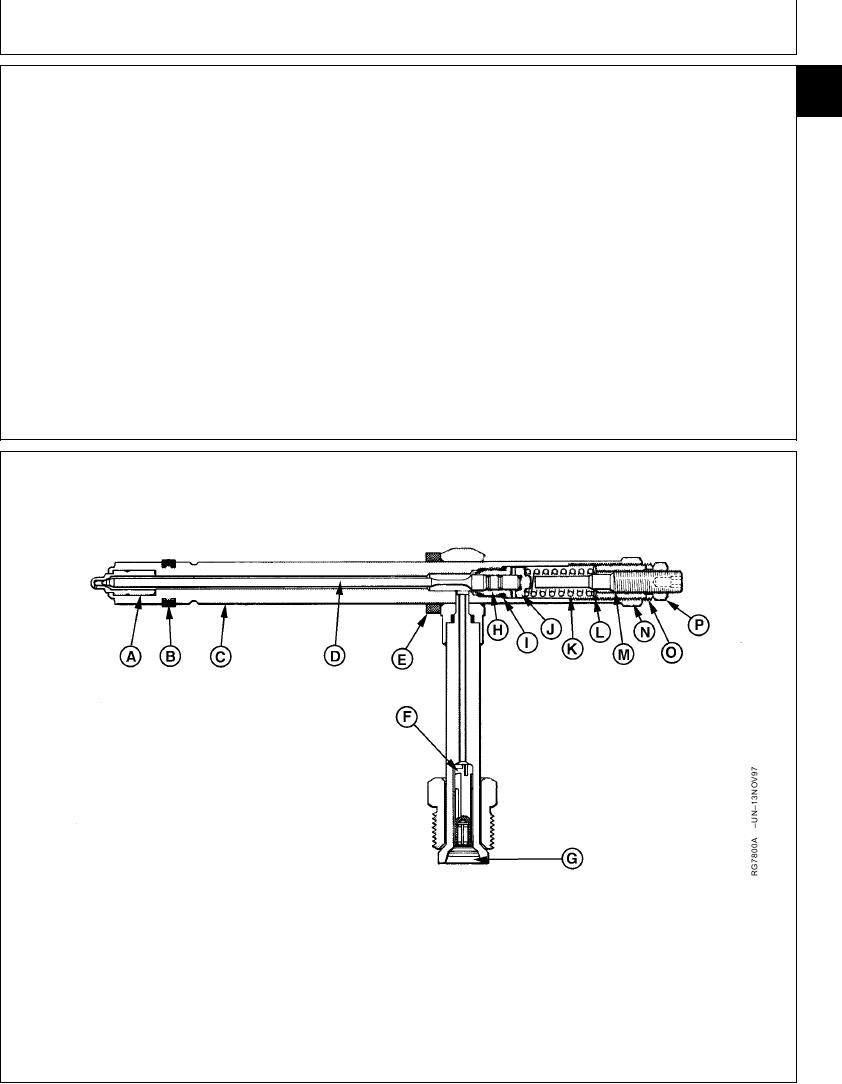

A--Nozzle Tip

E--Upper Sealing Washer

I--Upper Seal

M--Lift Adjusting Screw

B--Carbon Stop Seal

F--Edge-Type Filter

J--Spring Seat

N--Lock Nut

C--Nozzle Body

G--Fuel Inlet

K--Spring Screw

O--Pressure Adjusting

D--Nozzle Valve

H--Upper Guide

L--Spring Washer

P--Lock Nut

Continued on next page

RG,35,JW7591

1920NOV971/4

13-446