TM 5-3805-280-24-2

Fuel System

35

General Nozzle Repair Notes:

68

NOTE: Disassembly of nozzles is not recommended

unless servicing is indicated by nozzle operation

and testing.

Since dirt and water are the worst contaminants in the fuel

injection system, the working area, tools and cleaning

materials must be kept spotlessly clean. Whenever

possible, work in an isolated, dust-free area.

Cover the work bench with clean paper before beginning

disassembly of injection nozzles.

As parts are disassembled, place then in a pan of clean

diesel fuel and leave there until needed. Do not permit

these parts to strike each other.

Use a separate pan of clean fuel for washing parts before

assembly.

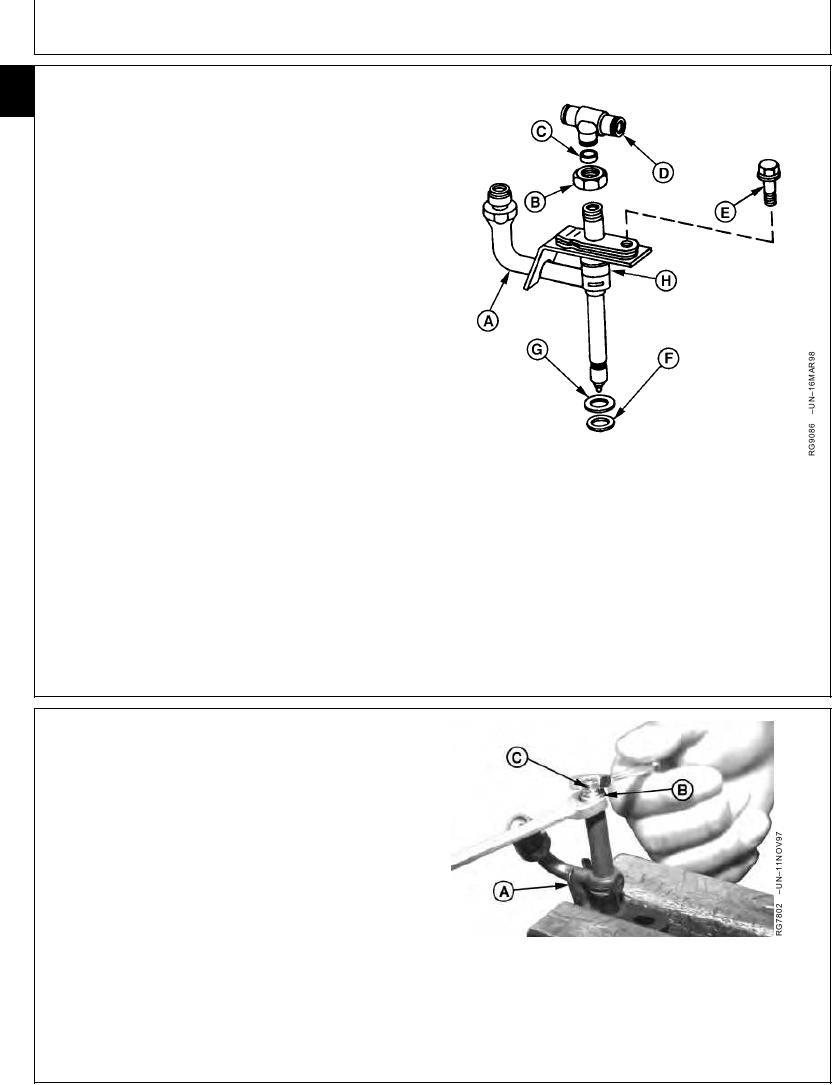

A--Nozzle Assembly

B--Tube Nut

C--Packing

D--Leak-Off-Fitting

E--Cap Screw

F--Carbon Stop Seal

G--Upper Sealing Washer

H--Spacer

RG,35,JW7591

1920NOV972/4

To Disassemble Fuel Injection Nozzle:

1. Place nozzle in ROS17787 Holding Fixture or nozzle

index clamp (A) and secure fixture or clamp in a vise.

2. Loosen pressure adjusting lock nut (B).

3. Back out lift adjusting screw lock nut (C) and lift

assembly.

4. Invert nozzle and allow pressure adjusting spring seat

and lift adjusting assembly to fall into your hand. Do

not bend stem during removal.

A--Nozzle Index Clamp

B--Pressure Adjusting Lock Nut

C--Lift Adjusting Lock Nut

Continued on next page

RG,35,JW7591

1920NOV973/4

13-447