TM 5-3805-280-24-2

UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 230LCR/230LCRD

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

(2) Rotate engine 360 and repeat step 1 for the

remaining intake and exhaust valves.

(3) Tighten jam nut to 27 Nm (20 lb-ft).

(4) Clean cylinder head and rocker arm cover

mating surfaces.

(5) Install rocker arm gasket. Do not use sealant on

gasket.

(6) Install rocker arm cover. Tighten screws to 35

Nm (26 lb-ft). Do not overtighten cap screws.

(7) Remove turning tool and timing pin.

(8) Install parts. Center muffler to turbocharger

inlet tube before fastening muffler into place.

46

Annually

Change Propel Gearbox Oil

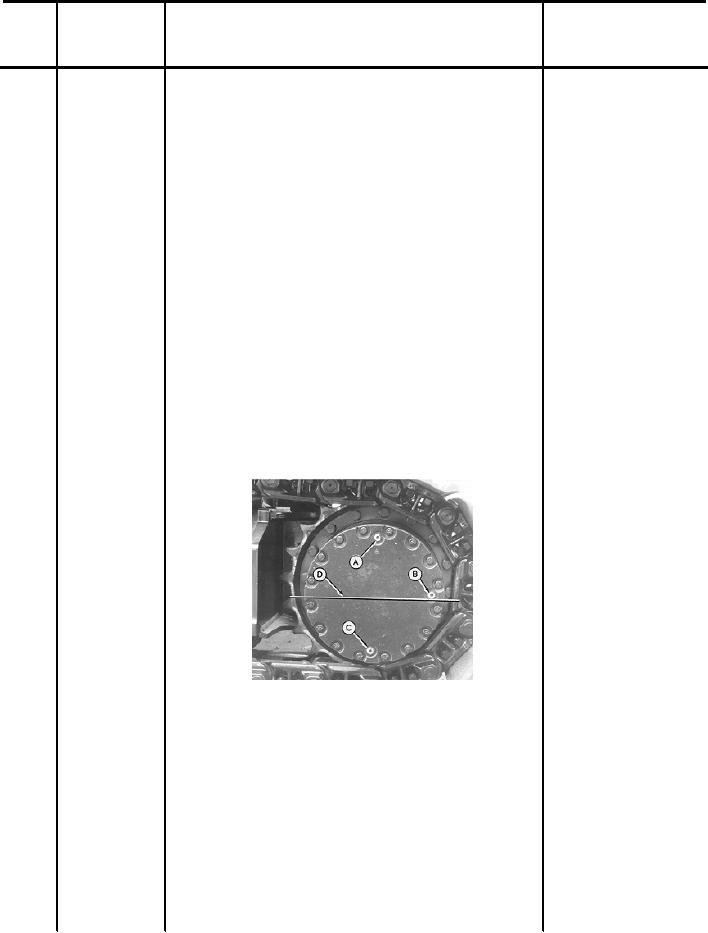

(1) Park machine on level ground rotating propel

gearbox until bottom of the oil level check

plug (B) is even with the horizontal centerline

(D).

(2) Lower boom to the ground.

(3) Turn auto-idle switch off.

(4) Run engine with engine rpm dial at 1/3 position

without load for 2 minutes.

CAUTION: Turbocharger may be damaged if

engine is not properly shut down.

A-32