TM 5-3805-281-10

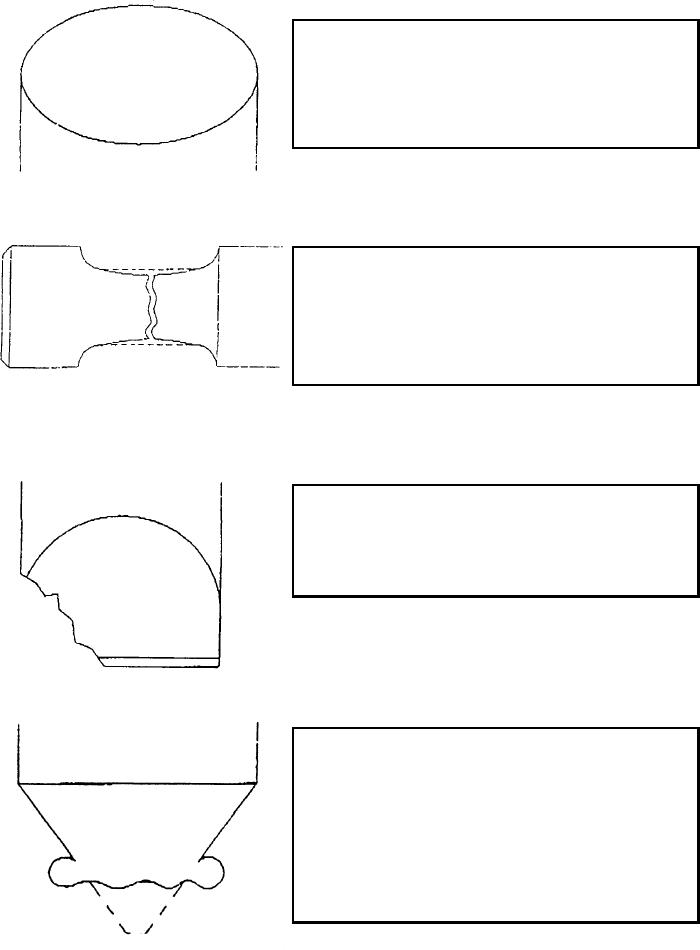

Cold Fracture

Cold temperatures can cause the tool to become brittle and

break. This failure can be avoided by warming the tool when

working in cold temperatures.

Break at Retaining Groove

This failure is a result of using a tool with worn or damaged

retainers. Any time a tool is replaced the tool retainers should

be inspected for wear and replaced if worn or damaged.

Breaking of Chisel Tip

This failure is caused by the improper contact between the

tool and the material being broken.

Mushrooming of Tip

This failure is caused by hammering too long without penetra-

tion of the material. This generates extreme heat and softens

the tools materials which then mushrooms. Once a tool has

been overheated, the properties of the tool's materials are

permanently altered. This change of properties can then lead

to premature failure of the tool. This damage can be prevented

by proper lubrication and operation.

7-47