TM 5-3805-281-10

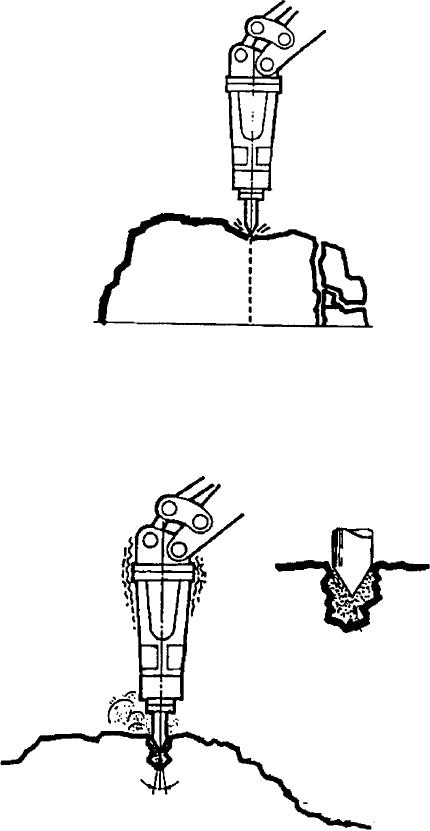

e) When breaking large blocks of rock, any protrusions should be broken off first, in order

to reduce the overall size of the block.

f) For secondary demolition, before starting the hammer, adjust the material to be bro-

ken so that it is on a hard, stable surface.

g) A small pocket of rock dust can sometimes occur in the"well" formed by the tool. The

hammer impact may be released on this, therefore not breaking the rock. The tool will

then overheat and may deform. The solutions to this are either to make another paral-

lel hole nearby, or to carry out small movements of the hammer to disburse the rock

dust. Do not continue in the same spot. This will waste the hydraulic power and

damage the tool.

7-42