TM 5-3805-281-10

COMMON CAUSES OF BREAKER DAMAGE

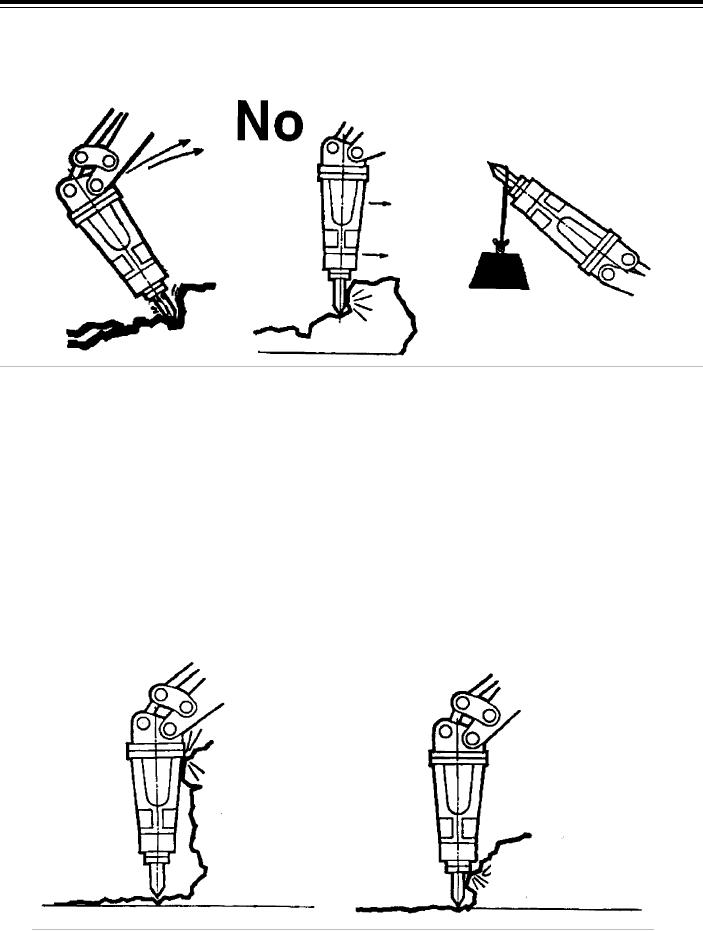

a) The hammer must not be used as a ripper, nor should it be used as a lever. Under

no circumstances should the tool be used as a hook to lift weights. This could cause

serious damage to the tool, the bushing and the housing.

b) The hammer must operate perpendicular to the work. This ensures that: the tools are

not forcibly stressed; bending stress does not occur; and the specific pressures in the

contact areas are maintained. This will greatly extend the life of the tool and the

bushings.

c) Check that the tool contact areas (especially the chuck housing) are well lubri-

cated and smooth. A properly lubricated tool will show streaks of grease below the

lower bushing on the tool shank. Remove any bumps or rough areas with a soft grind-

ing wheel and wire brush. The point of a chisel tool can be re-sharpened in the same

way. Tools should be rotated 180 to evenly distribute the wear.

d) The hammer must be free to operate without any obstructions, chafing or interference.

There should also be no obstruction between the hammer and the tool.