TM 5-3805-281-10

TYPICAL TOOL FAILURES

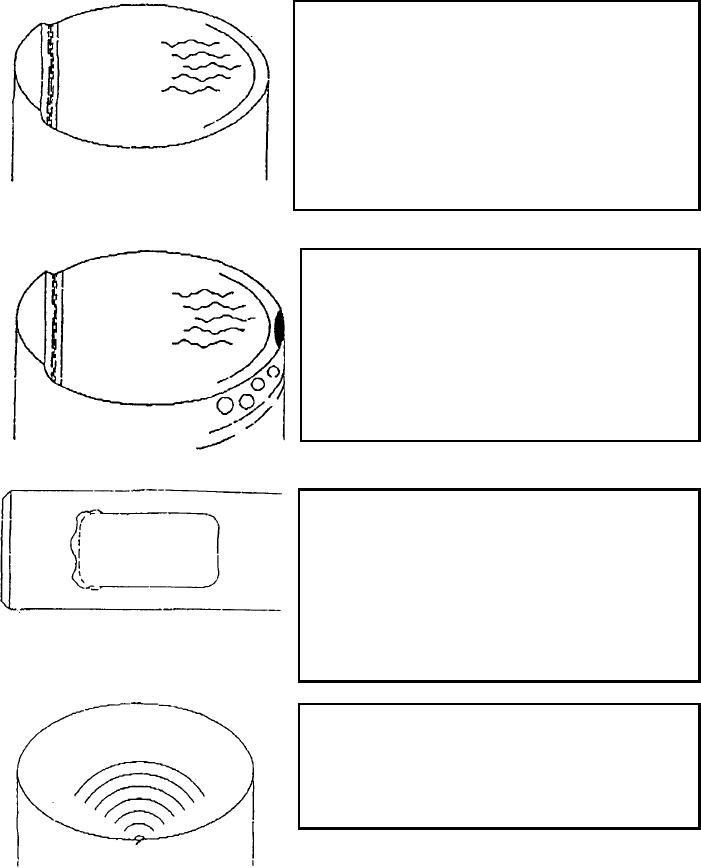

Misalignment or Pry Break

The bending stress exceeds the materials strength and the tool

snaps. Caused by working at an incorrect angle or using the

tool for mechanical leverage. The failure usually occurs near

the tool bushing's front face. This failure can also be caused

by the breaker slipping while hammering at angles not

perpendicular to the surface of the material being broken.

The failure type is a brittle type and typically has a lip

formation.

Seizing in the Tool Bushing

Strong side loading and striking the tool at the same time

causes the tool and bushing surface to be damaged. This

failure is cause by incorrect or insufficient lubrication. The

failure generally occurs in the front tool bushing area. The

failure type is a fatigue fracture starting at the surface of

the tool.

Blank or Dry Firing

Occurs when the working end of the tool is not in proper

contact with the material being broken. The failure can also

occur when breaking through the material and the breaker

strikes the tool a last time. When struck without resistance at

the working end the tool , the tool stops abruptly when it is

stopped by the retainers instead of the material. This results

in breaking and deformation in the retaining groove.

Mechanical Damage on the Tool"s Surface

This is caused by heavy scratching on the tools surface. The

failure usually occurs outside the tool bushing. The failure is

generally a fatigue type fracture.

7-46