TM 5-3805-281-10

BREAKER TOOL SELECTION

Choose the most suitable tool for the operation required. For the breaking of boulders,

use MOIL or OLGIVE points. In restricted areas, such as trenches, use CHISEL points

and proceed in-line with the work face. In particularly narrow places, progress gradually,

through small sections of material, making the most of the regularity of the striking fre

quency. Keep the front of the hammer parallel to the operator, with the machine arm

drawn up. This will avoid damage to the tool, especially during cutting and squaring orks.

The COBRA point is recommended for EARTH-MOVING jobs, or for particularly difficult

materials.

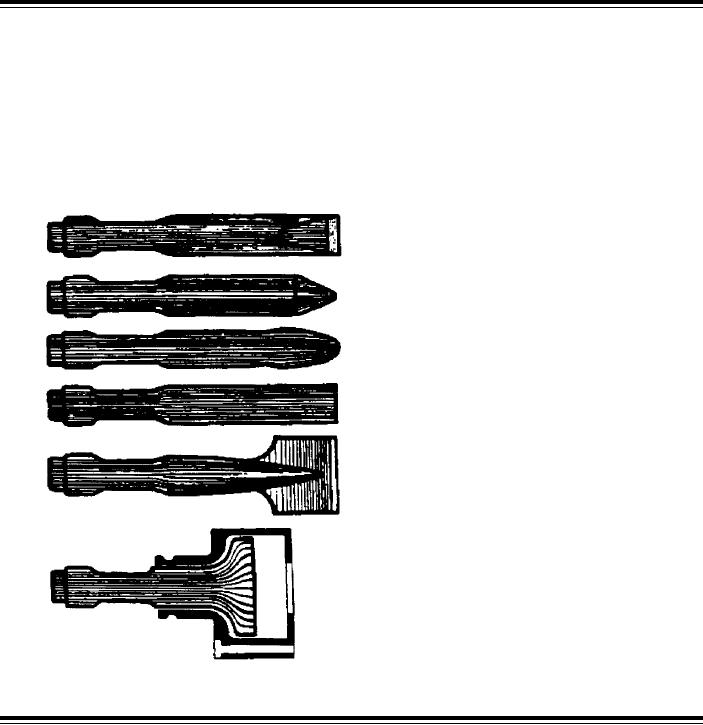

Point and Recommended Use

1) Chisel All earth-moving duties or excavations

1

in narrow trenches or stratified soil or rock up to

medium rock.

2

2) Moil Demolition of rocks and materials, not

stratified rock, up to medium hardness.

3

3) Olgive Demolition of hard to very hard rock.

4) Blank or Blunt Demolition of rocks up to

4

medium hardness to be broken into smaller pieces.

5) Asphalt Cutter or Spade Cutting of

5

concrete paving, brick walls or turf.

6) Pole or Pipe Cutter Driving pipes, poles

or preshaped metal objects (IE. shaped metal

gaurdrail poles) into different materials.

6

TOOL BREAKAGE ANALYSIS

DESCRIPTION OF TYPICAL STRESS

IN ORDER TO UNDERSTAND THE COMPLEXITY OF THE STRESS PHENOMENA THAT RESULTS IN TOOL BREAKAGE, SOME

GENERAL INFORMATION NEEDS TO BE ADDRESSED. THE TOOL IS CONSIDERED AN ELASTIC ELEMENT DESIGNED TO

TRANSMIT SHOCK OR KINETIC ENERGY FROM THE HAMMER PISTON TO THE MATERIAL TO BE DEMOLISHED.

* The typical tool break starts as a small fracture in the surface of the tool that is the most

stressed area. Eventually a surface crack is created from: micro-welds from surface

work hardening; localized heating and cooling on the tool surface; and tension and