TM 5-3805-281-10

BREAKER LUBRICATION

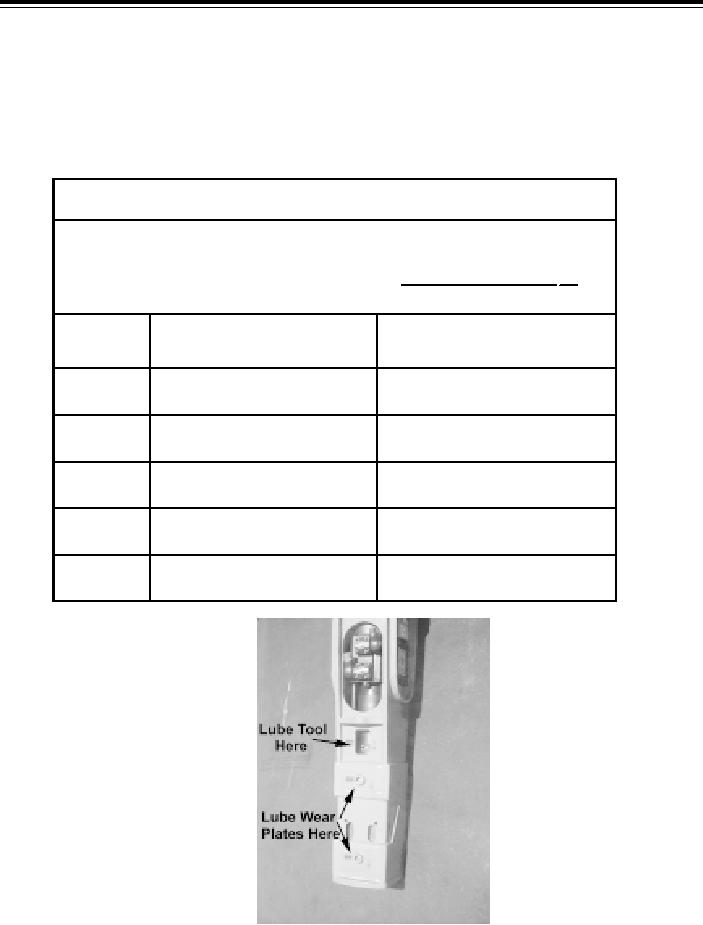

It is essential to lubricate the tool using the grease chart below as a guideline. If working

in dusty conditions, the tool should be greased even more frequently (See the picture

below for proper greasing points). The tool should also be removed weekly and the

cavity cleaned and packed with new grease. The tool must always have grease on the

hammer contact area. YOU CAN SAVE TIME AND ENERGY BY USING AN INDECO

POWER LUBE SYSTEM TO AUTOMATICALLY CARRY OUT THIS FUNCTION.

INDECO B reake r Greasing Schedule

Failure to follow these recommendations may result in low

WARNING!!!

production and increased tool failure.

(All recommendations are minimums and tool lubrication must be

increased in dusty conditions.)

Model

Tool

Wear Plates

Lube Rate with Grease Gun

Lube Rate with Grease Gun

MES 181

Every 2 hours - Approximately 15

Once per day - Approximately 2 - 3

thru 553

pumps of grease.

pumps each wear plate.

MES 621

Every 2 hours - Approximately 30

Once per day - Approximately 2 - 3

thru 1200

pumps of grease.

pumps each wear plate.

MES 1500

Every 2 hours - Approximately 40

Once per day - Approximately 2 - 3

thru 2000

pumps of grease.

pumps each wear plate.

MES 2500

Every 2 hours - Approximately 60

Once per day - Approximately 2 - 3

thru 3500

pumps of grease.

pumps each wear plate.

MES 5000

Use of an INDECO Power Lube Syste

Once per day - Approximately 2 - 3

and larger

is Recommended.

pumps each wear plate.

Lube Point