TM 5-3805-281-10

Maintenance--Every 500 Hours

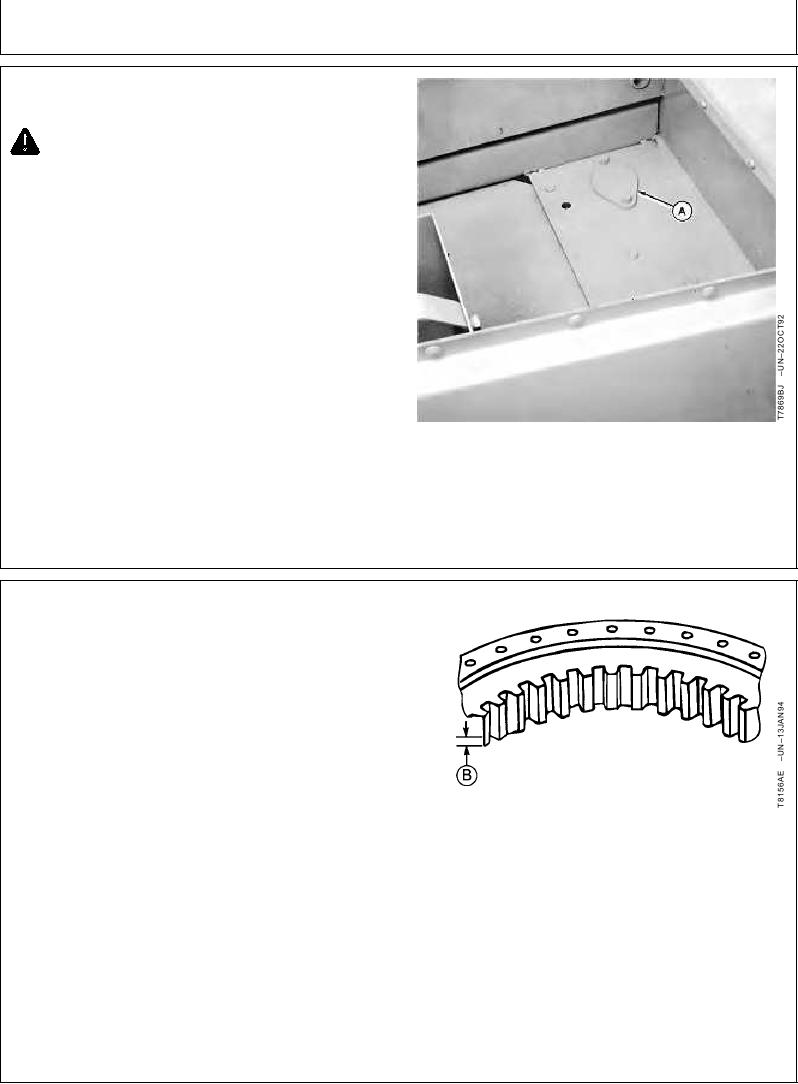

GREASE SWING BEARING GEAR

CAUTION: Prevent possible injury from

unexpected machine movement if controls are

moved by another person. Lubricating swing

bearing gear and rotating the upperstructure

must be done by one person.

1. Remove access cover (A) to swing gear.

Located In Tool Box

A--Access Cover

CED,TX14740,6100

1923APR981/2

2. Grease must be 13--25 mm (1/2--1 in.) (B) deep

measured from the bottom of the ring gear. The grease

must also be free of contamination by dirt and water.

If the grease is contaminated, remove grease and

replace with clean grease.

IMPORTANT: If water or mud is found in swing gear

area, see Operating in Water and Mud in

Operating the Machine chapter.

3. Add grease as required (approximately 0.113 kg (1/4

lb) every 90). (See Fuels and Lubricants chapter.)

B--Grease Depth

IMPORTANT: Excessive grease can damage the

swing gearbox seal.

4. Remove excessive grease that extrudes over the top of

the swing drive pinion.

5. Install access cover.

CED,TX14740,6100

1923APR982/2