TM 5-3805-281-10

Maintenance--Every 2000 Hours

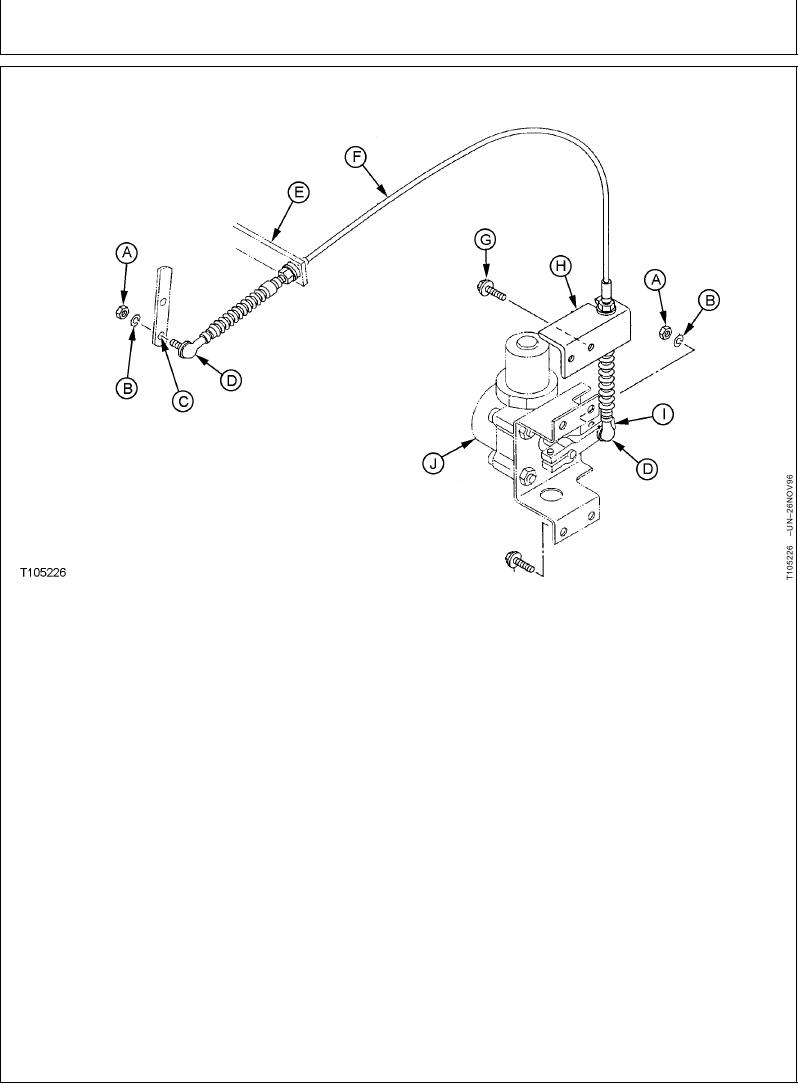

ENGINE SPEED CONTROL CABLE ADJUSTMENT

A--Nut (2 used)

D--Ball Joint (2 used)

G--Cap Screw and Lock

I--Engine Control Motor

B--Lock Washer (2 used)

E--Bracket

Washer (6 used)

Arm

C--Injection Pump Lever

F--Speed Control Cable

H--Bracket

J--Engine Control Motor

cable are centered in brackets. As needed, adjust

IMPORTANT: The ball joints (D) are installed on

cable in brackets to connect ball joint to lever or

the cable to full thread engagement.

arm.

A ball joint can be used to lengthen

a cable end, if needed, but must

3. Connect ball joint to the outer hole of engine control

have at least 6 mm (1/4 in.) of thread

motor arm (I).

engagement to avoid stripping the

threads on cable end.

4. Do Engine Control Motor Adjustment and then the

Engine Speed Learning Procedure. (See

1. Install ball joints (D) to full thread engagement.

procedures in this chapter.)

Tighten nuts.

2. Install speed control cable (F) in brackets (E and

H). Initially, tighten nuts so threaded portions of

CED,TX14740,6096

1920APR981/1