TM 5-3805-281-24-1

Group 20

Adjustments

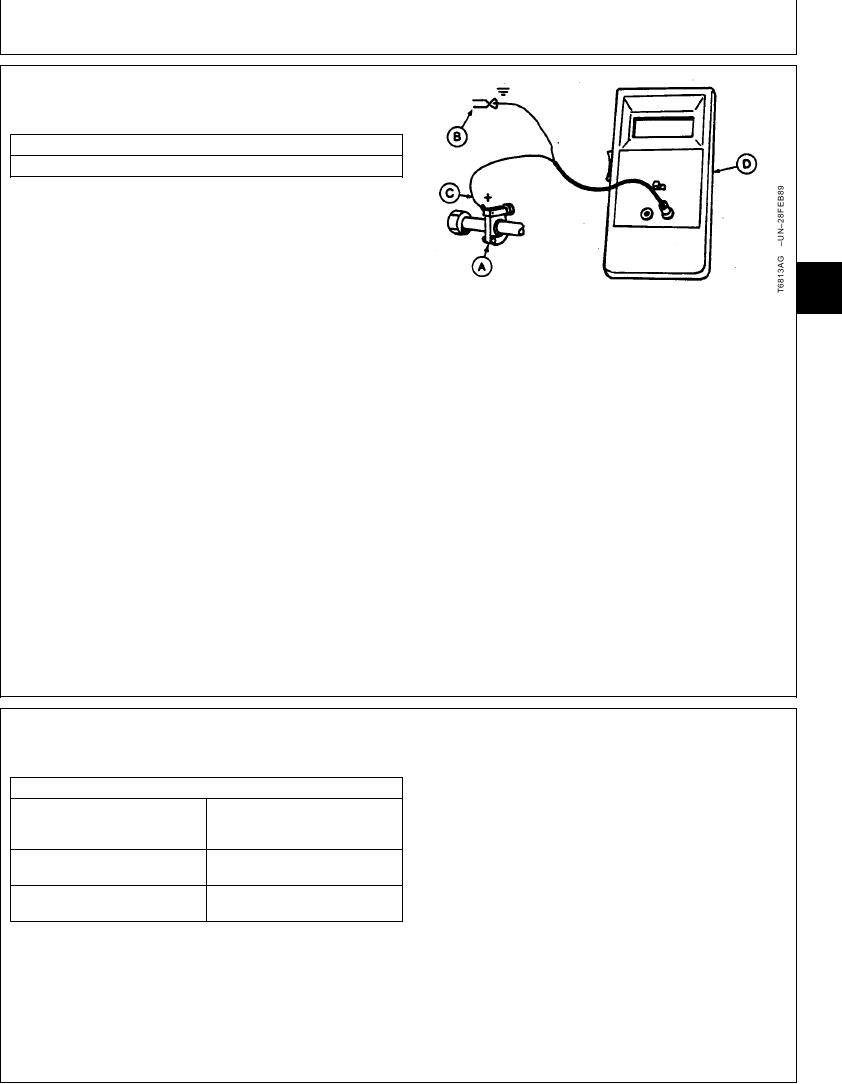

JT05801 CLAMP-ON ELECTRONIC

TACHOMETER INSTALLATION

SERVICE EQUIPMENT AND TOOLS

JT05801 Clamp-On Electronic Tachometer

1. Before installing clamp-on electronic tachometer,

remove the paint from a straight section of injection

line within 100 mm (4 in.) of No. 1 injection nozzle.

Use emery cloth to remove the paint.

9010

20

2. Install the clamp-on transducer (A). Tighten finger tight

1

only--DO NOT overtighten.

A--Clamp-On Transducer

B--Black Clip (-)

3. Connect the red clip (+) (C) to the clamp-on

C--Red Clip (+)

transducer.

D--Digital Readout Unit

4. Connect the black clip (-) (B) to a ground connection

such as the head of a cap screw or other metal part on

engine.

5. Start the engine. Check for a reading on the digital

readout unit (D).

CED,TX08227,2879

1911NOV971/1

FUEL SHUT-OFF SOLENOID LINKAGE

CHECK AND ADJUSTMENT

SPECIFICATIONS

Fuel Shut-Off Solenoid Ball Joint

3--6 mm (1/8--1/4 in.) short of

Hole-to-Fuel Shut-Off Lever Hole

alignment.

Distance

Fuel Shut-Off Solenoid

8 Nm (70 lb-in.)

Plunger-to-Ball Joint Nut Torque

Fuel Shut-Off Lever-to-Stop

within 3 mm (0.125 in.) of stop

Position Stop Distance

position stop

Continued on next page

TX,05,GG2305 1908JUN981/3