TM 5-3805-281-24-1

Sub-System Diagnostics

HIGH POWER (HP)

YES: Indicator lamp or

MODE SWITCH (S12)

controller has failed.

HARNESS CHECK

Replace.

NO: Harness has failed.

Repair.

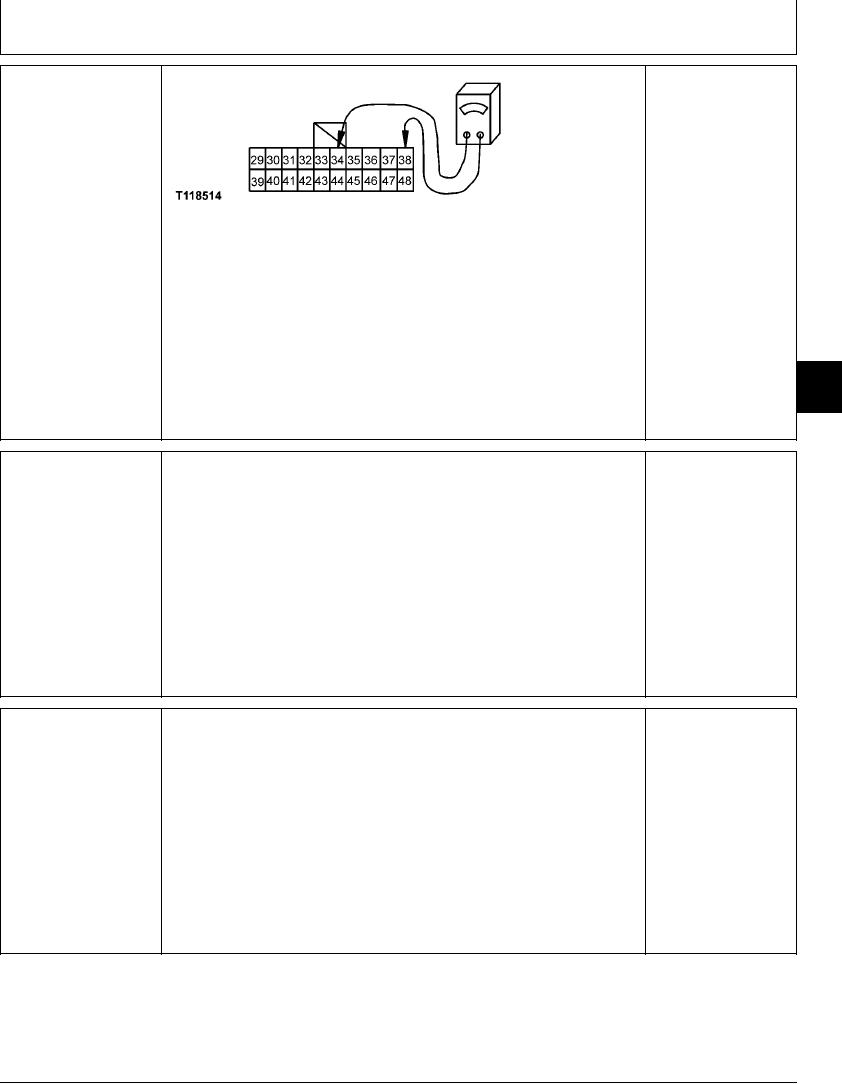

T118514 UN21NOV98

Turn key switch OFF.

Disconnect 20-pin harness connector from monitor controller and display.

Connect ohmmeter between pins 34 and 38 of harness connector.

Measure continuity with high power (HP) mode switch in OFF and ON positions.

Does ohmmeter read open with switch in OFF position, and continuity with switch in

9015

ON position?

15

55

1/1

Turn key switch ON.

YES: Switch and

WORK MODE

indicators are OK.

SELECTION SWITCH

Push WORK MODE switch several times to cycle through all work mode selections

(S7), DIG MODE

(dig, grading precision, attachments).

NO: If modes do not

INDICATOR LIGHT (H1),

change, switch or monitor

GRADING MODE

controller has failed.

Does mode selection change when switch is pressed?

INDICATOR LIGHT (H2),

Repair or replace.

PRECISION MODE

Does each mode indicator come ON as mode is selected?

INDICATOR LIGHT (H3)

Replace indicator lamp

AND ATTACHMENT

that does not come ON.

MODE INDICATOR LIGHT

(H4) CHECK

1/1

Turn key switch ON.

AUTO IDLE SWITCH

YES: Switch and indicator

(S13) AND AUTO IDLE

are OK.

MODE INDICATOR LIGHT

Push auto idle (A/I) switch.

(H7) CHECK

NO: Check indicator

Does auto idle (A/I) indicator come ON?

lamp. If lamp is OK,

switch or controller has

failed. Replace.

Push auto idle (A/I) again.

Does auto idle (A/I) indicator go OFF?

1/1

4-123