TM 5-3805-281-24-1

Tests

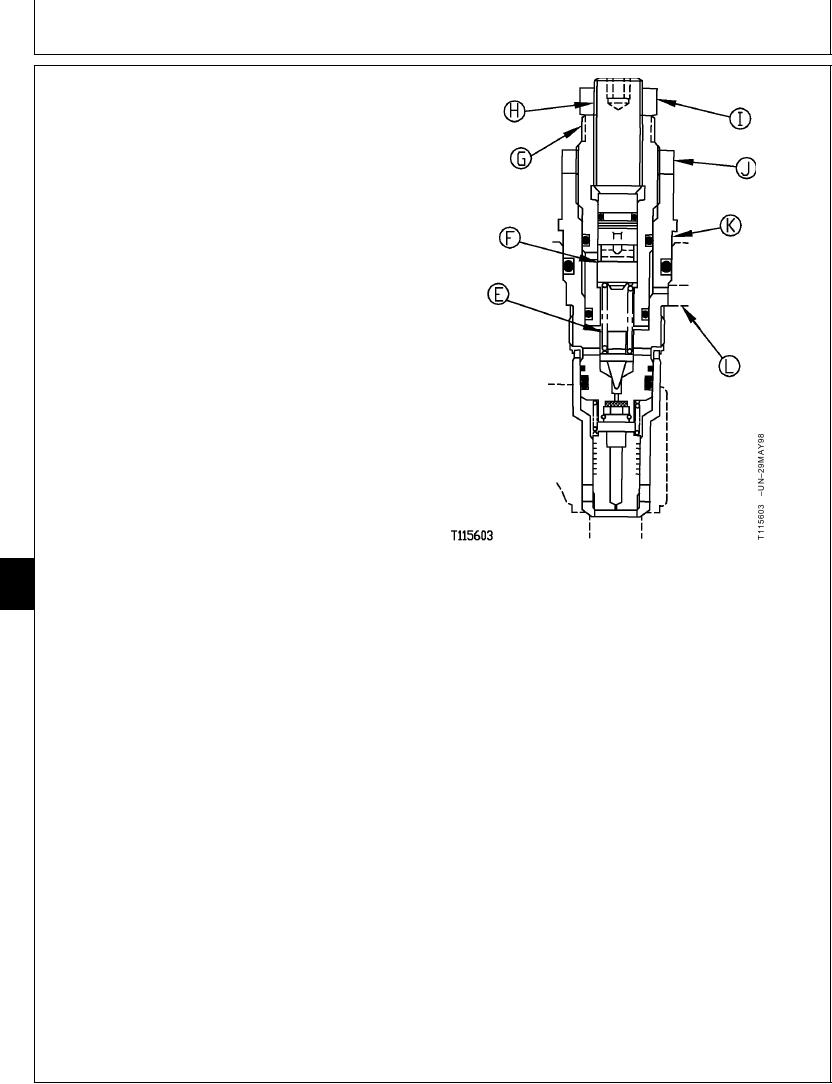

a. Loosen the 22 mm nut (I).

NOTE: The higher pressure setting for power boost must

be adjusted first and then the lower pressure

setting for the system relief valve. Turning the

adjusting screw (H) in pushes the piston (F) down

compressing the pilot poppet spring (E) increasing

the pressure setting to the power boost pressure

setting.

b. Turn the adjusting screw (H) in until piston (F) is

against bottom of bore in adjusting plug (G). Tighten

the nut just enough to hold the adjusting screw.

c. Loosen the 32 mm nut (J).

d. Turn adjusting plug (G) in to increase power boost

pressure; turn plug out to decrease power boost

pressure.

Per 1/4 Turn of Adjusting Plug Approximate

Change--Specification

Pressure .................................................... 4 415 kPa (44.1 bar) (640 psi)

e. Hold adjusting plug and then tighten 32 mm nut.

Adjusting Plug-to-Cartridge Nut--Specification

9025

E--Pilot Poppet Spring

25

F--Piston

Torque ........................................................... 29 Nm (22 lb-ft) (260 lb-in.)

78

G--Adjusting Plug

H--Adjusting Screw

f. Loosen the 22 mm nut.

I--22 mm Nut

J--32 mm Nut

K--System Relief and Power Boost Valve

g. Turn the adjusting screw out to decrease pressure

L--Power Boost Pilot Signal Passage

to get the specified system relief valve pressure.

Per 1/4 Turn of Adjusting Screw Approximate Change--

Specification

Pressure .................................................... 4 415 kPa (44.1 bar) (640 psi)

h. Hold adjusting screw and then tighten 22 mm nut.

Adjusting Screw-to-Adjusting Plug Nut--Specification

Torque ........................................................... 29 Nm (22 lb-ft) (260 lb-in.)

9. Check the pressure settings again.

CED,TX08227,3033

1918MAR985/5

6-225