TM 5-3805-281-24-1

Track System

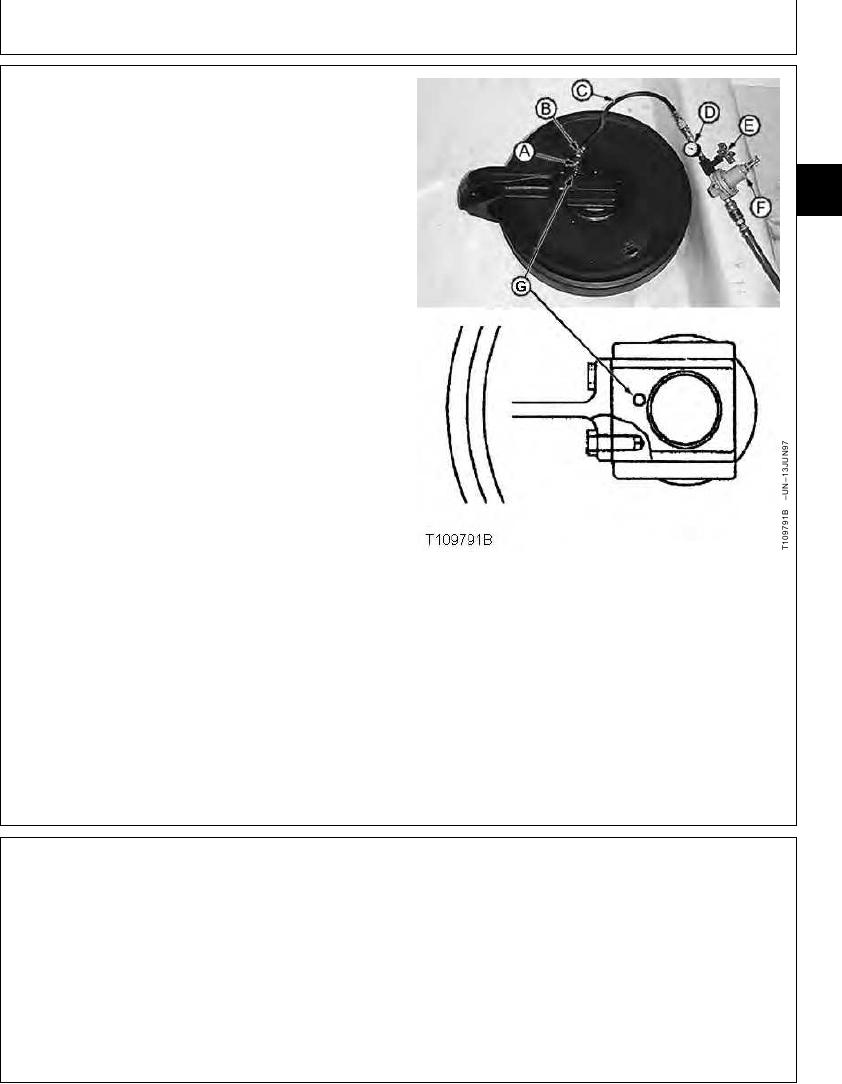

TEST FRONT IDLER FOR OIL LEAKAGE

1. Turn shaft several turns to seat metal face seals.

2. Remove plug (G).

01

0130

3. Install parts (A--F) as shown. Plug, barbed adapter,

41

and connector are from a leak detector kit such as the

D05361ST Rubber Stopper/Leak Detector Kit.

4. Hold plug so it is not pushed out, slowly pressurize oil

cavity using air.

Front Idler Oil Cavity--Specification

Pressure ................................................. 110 18 kPa (1.1 0.3 bar) (16

4 psi)

5. Close valve and wait for a minimum of 30 seconds to

check for oil leakage. Check gauge to see if air

pressure has decreased.

6. If there is external leakage, disassemble idler and

replace parts as necessary.

7. Check oil level in idler. If oil level is down and there is

no external leakage, check for a leak from oil cavity to

interior of idler wheel.

A--Plug, Adapter and Connector

B--Connector 1/8 M NPT x 7/16-20 M 37

8. Clean threads of plug using cure primer.

C--Hose

D--Pressure Gauge

9. Apply pipe sealant to threads of plug. Install and

E--Snubber (Needle) Valve

tighten plug.

F--Air Pressure Regulator

G--Drain Plug

CED,OUOE023,2281 1930JAN981/1

REMOVE AND INSTALL TRACK ADJUSTER

CYLINDER AND RECOIL SPRING

1. Remove track chain and front idler. (See procedures in

this group.)

Continued on next page

CED,OUOE023,140

1926MAY981/3