TM 5-3805-281-24-2

Cylinder Head and Valves

DIAGNOSING HEAD GASKET JOINT

FAILURES

Head gasket failures generally fall into three categories:

Combustion seal failures.

Coolant seal failures.

Oil seal failures.

Combustion seal failures occur when combustion gases

escape between cylinder head and head gasket

combustion flange, or between combustion flange and

cylinder liner. Leaking combustion gases may vent to an

adjacent cylinder, to a coolant or oil passage, or

externally.

Coolant or oil seal failures occur when oil or coolant

escapes between cylinder head and gasket body, or

between cylinder block and gasket body. The oil or

coolant may leak to an adjacent coolant or oil passage, or

externally. Since oil and coolant passages are primarily on

right hand (camshaft) side of engine, fluid leaks are most

likely to occur in that area.

Follow these diagnostic procedures when a head gasket

joint failure occurs, or is suspected.

Diagnosing Cylinder Head Gasket Joints

1. Before starting or disassembling engine, conduct a

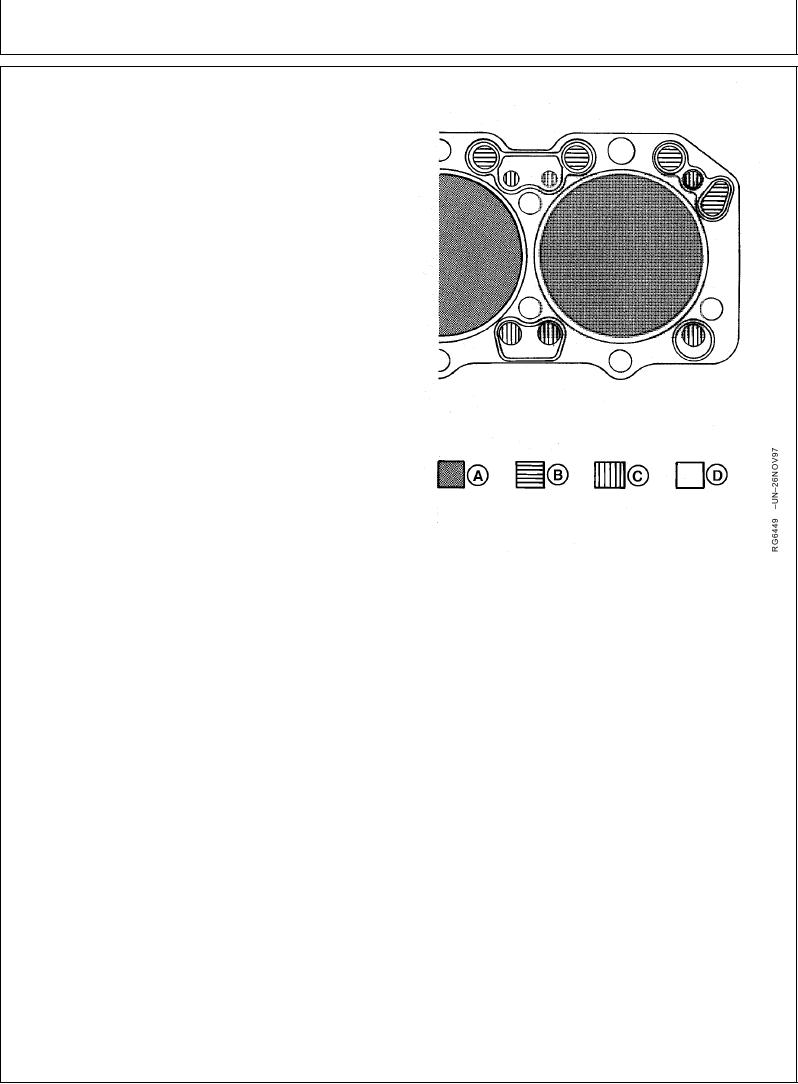

A--Combustion Sealing Areas

visual inspection of machine, and note any of the

B--Oil Sealing Areas (Push Rod)

following:

C--Coolant Sealing Areas

D--Cylinder Head Cap Screws

Oil or coolant in head gasket seam, or on adjacent

surfaces. Especially right rear corner of gasket joint.

Displacement of gasket from normal position.

Discoloration or soot from combustion gas leakage.

Leaking radiator, overflow tank, or hoses.

Leaking coolant from water pump weep hole.

Damaged or incorrect radiator, fan, or shroud.

Obstructed air flow or coolant flow.

Worn or slipping belts.

Damaged or incorrect radiator pressure cap.

Presence of oil in coolant.

Low coolant levels.

Improper coolant.

Unusually high or low oil levels.

Unburned fuel or coolant in exhaust system.

Continued on next page

RG,RG34710,1073

1923OCT971/4