TM 5-3805-281-24-2

Cylinder Head and Valves

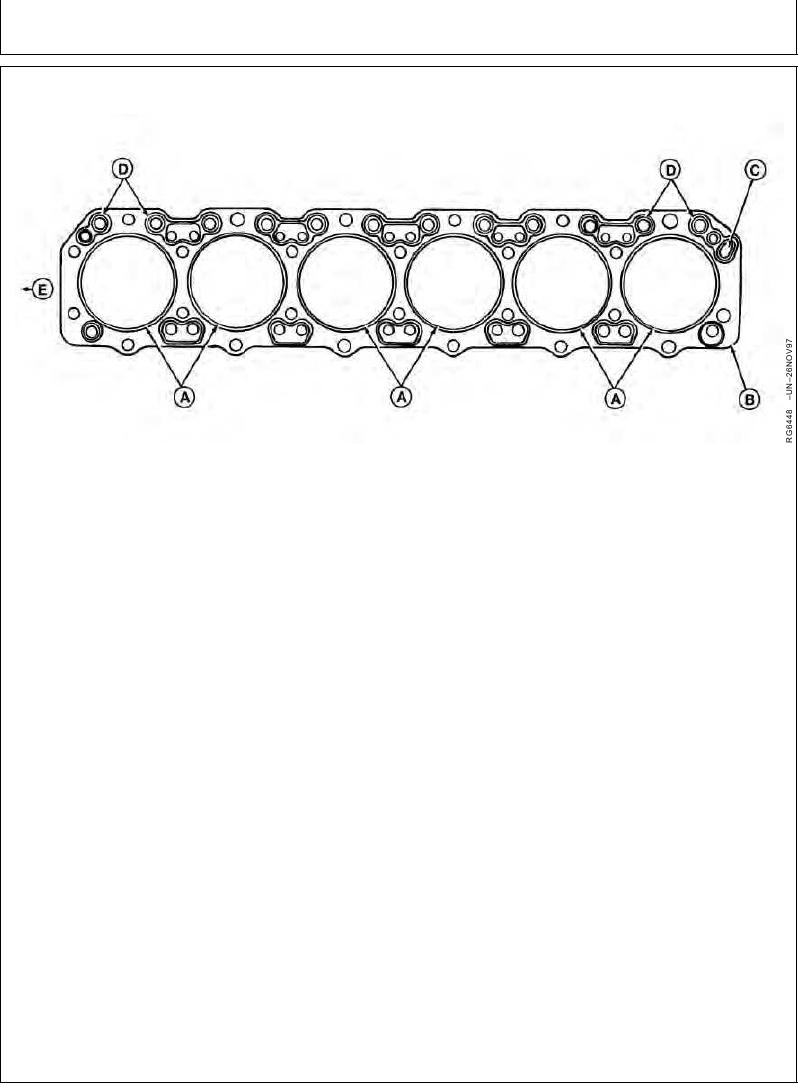

HEAD GASKET INSPECTION AND REPAIR SEQUENCE

Inspecting Cylinder Head Gasket

A--Combustion Seals

B--Gasket Body

D--Elastomer Beading

E--Front of Engine

(Flange)

C--Rocker Arm Oil Port

Strips

Adjacent body area burned/eroded.

The following inspection procedures are recommended

Fire ring severed/displaced/missing.

whenever a head gasket joint failure occurs, or when

Flange sealing pattern eccentric/contains voids.

joint disassembly takes place.

Discoloration of flange and adjacent body areas.

Flange surfaces rough/abraided/channelled.

1. Review historical data relating to machine

operation, maintenance and repair, along with

Examine gasket body (B) for the following:

diagnostic observations. Note all areas requiring

further inspection and analysis.

Combustion gas erosion paths or soot deposits

originating at combustion seals.

2. Remove rocker arm cover and check for presence

Extreme discoloration/hardening/embrittlement in

of coolant in the oil.

localized areas.

O-ring seal missing/damaged in port area (C).

3. Record head cap screw torques prior to removal.

Elastomer missing/damaged in port area (D).

Upon removal, check cap screw length differences.

Oil or coolant paths from port areas.

Localized areas of low compression.

4. Remove cylinder head using appropriate lifting

devices to prevent handling damage to head

6. Before cleaning components, inspect head, block,

gasket. (See REMOVE CYLINDER HEAD in

and liners for evidence of combustion gas and fluid

Group 05.)

leakage. Inspect cylinders and valve ports for

unusual deposits.

5. Observe surfaces of removed head gasket.

7. Clean block, head, liners, and cap screws. (See

Examine combustion seals (A) for the following:

Groups 05 and 10.)

Flange severed/expanded/cracked/deformed.

Continued on next page

RG,RG34710,1074

1923OCT971/2