TM 5-3805-281-24-2

Cylinder Block, Liners, Pistons, and Rods

3. Clean block thoroughly using cleaning solvent,

pressure steam, or a hot tank.

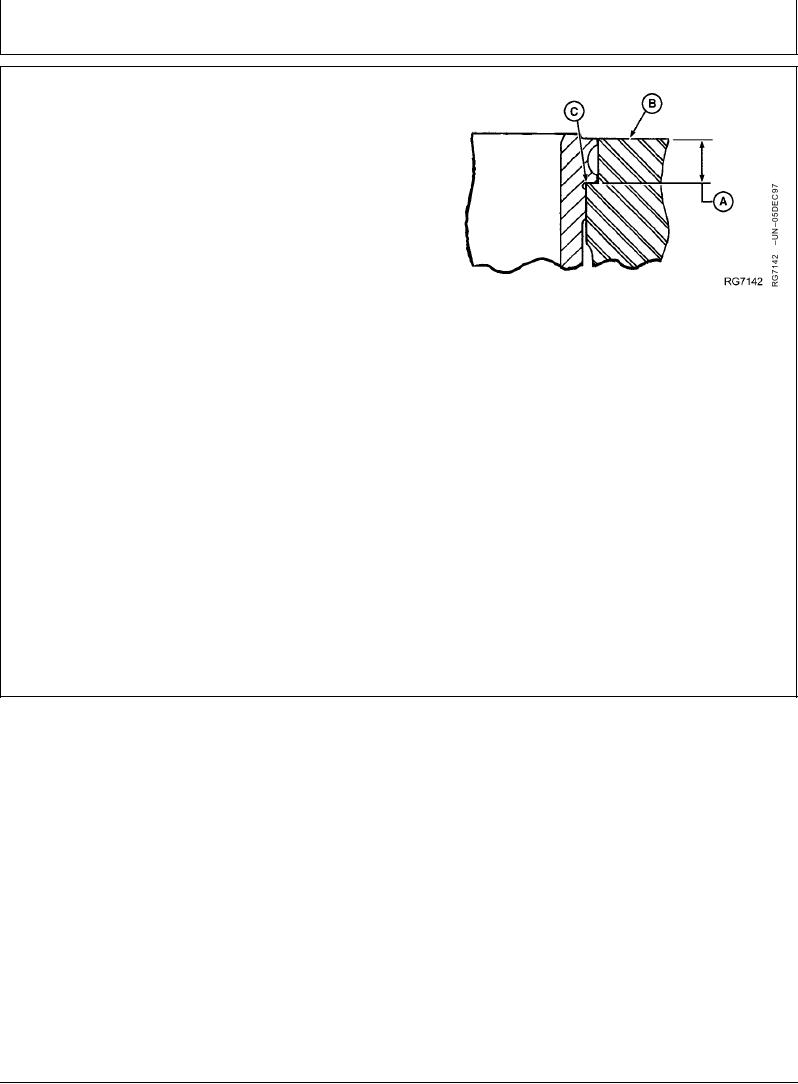

4. Inspect liner support flange (C) for burrs. If burrs are

present, use a small half-moon file and LIGHTLY file

(in a circular motion) burr off at approximately a 60

angle. DO NOT let file hit top deck of cylinder block (B)

while filing.

NOTE: DO NOT file liner support flange excessively.

Excess filing can damage liner support flange and

allow an improper liner fit. Thoroughly clean all

Measuring Liner Flange Counterbore Depth in Block

filings from cylinder block.

5. Measure liner flange counterbore depth (A) in block

and compare with specification given below.

Cylinder Block Counterbore--Specification

Depth ......................................................................... 11.913--11.963 mm

(0.469--0.471 in.)

Carefully inspect block for cracks or any other physical

damage. If a cracked block is suspected, pressure-test the

block. A procedure for pressure testing is outlined in FOS

(Fundamentals of Service) Manual-ENGINES. Replace

block if there is evidence of a crack or physical damage.

RG,RG34710,1134

1923OCT972/2

11-177