TM 5-3805-281-24-2

Crankshaft, Main Bearings, and Flywheel

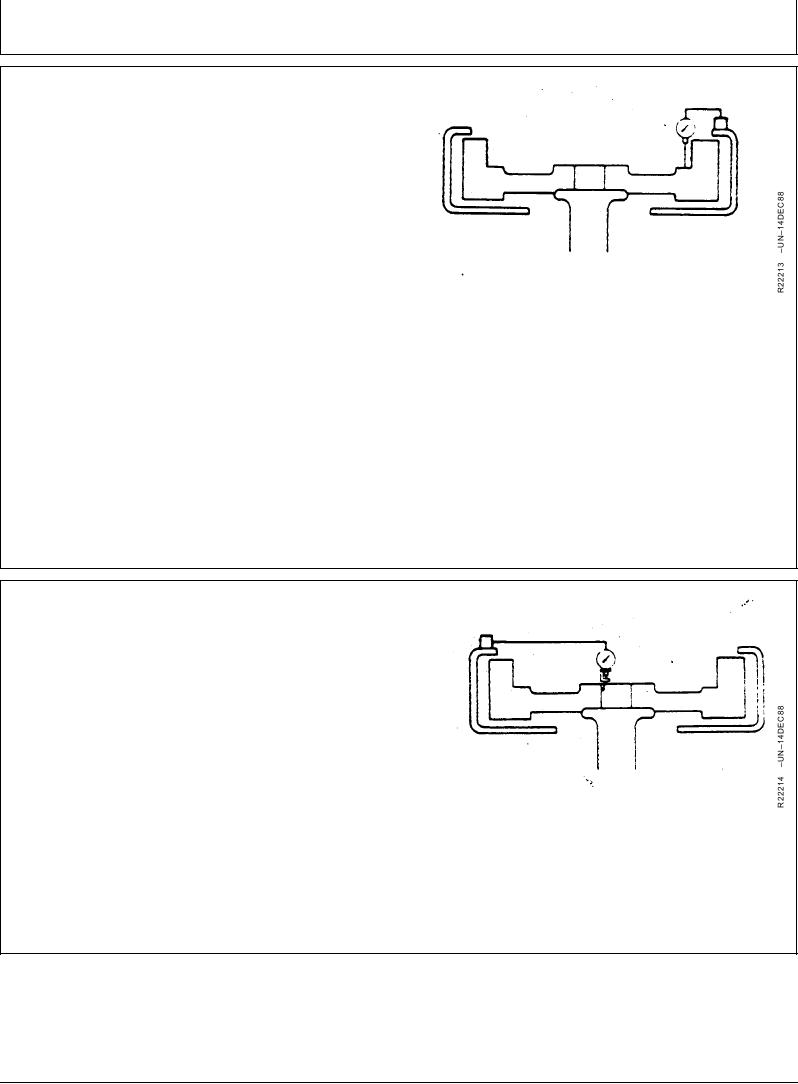

CHECK FLYWHEEL FACE FLATNESS

1. Mount dial indicator base on flywheel housing. Position

pointer to contact driving ring mounting surface. Do not

allow pointer to contact driving ring mounting holes.

IMPORTANT: Maintain constant end pressure on

crankshaft to hold shaft against thrust

bearing when measuring flywheel face

runout.

2. Rotate flywheel by turning crankshaft. Read total dial

indicator movement. Resurface flywheel face or

replace as required.

Flywheel Face--Specification

Flatness ...................................................... 0.23 mm (0.009 in.) maximum

variation

Flatness .................................................. 0.013 mm (0.0005 in.) maximum

variation per 25 mm (1.0 in.) of

travel

RG,RG34710,1160

1923OCT971/1

CHECK PILOT BEARING BORE

CONCENTRICITY

1. Mount dial indicator on flywheel housing face and

position pointer to contact I.D. of pilot bearing bore in

flywheel.

2. Rotate flywheel by turning crankshaft. Read total dial

indicator movement.

Flywheel Pilot Bearing--Specification

Bore Concentricity .................................... 0.127 mm (0.005 in.) maximum

Checking Flywheel Pilot Bearing Bore

variation

RG,RG34710,1161

1923OCT971/1